How Alu-zinc Coil is Transforming Industrial Equipment

2025-09-24

Introduction to Alu-zinc Coils and Their Industrial Significance

Alu-zinc coils have emerged as a groundbreaking material in the industrial sector, particularly in equipment manufacturing. This innovative alloy, which combines aluminum and zinc, offers remarkable resistance to corrosion, enhanced durability, and excellent thermal performance. As industries seek more efficient and long-lasting mate

Introduction to Alu-zinc Coils and Their Industrial Significance

Alu-zinc coils have emerged as a groundbreaking material in the industrial sector, particularly in equipment manufacturing. This innovative alloy, which combines aluminum and zinc, offers remarkable resistance to corrosion, enhanced durability, and excellent thermal performance. As industries seek more efficient and long-lasting materials, Alu-zinc coils are setting new standards in quality and longevity.

What is Alu-zinc Coil?

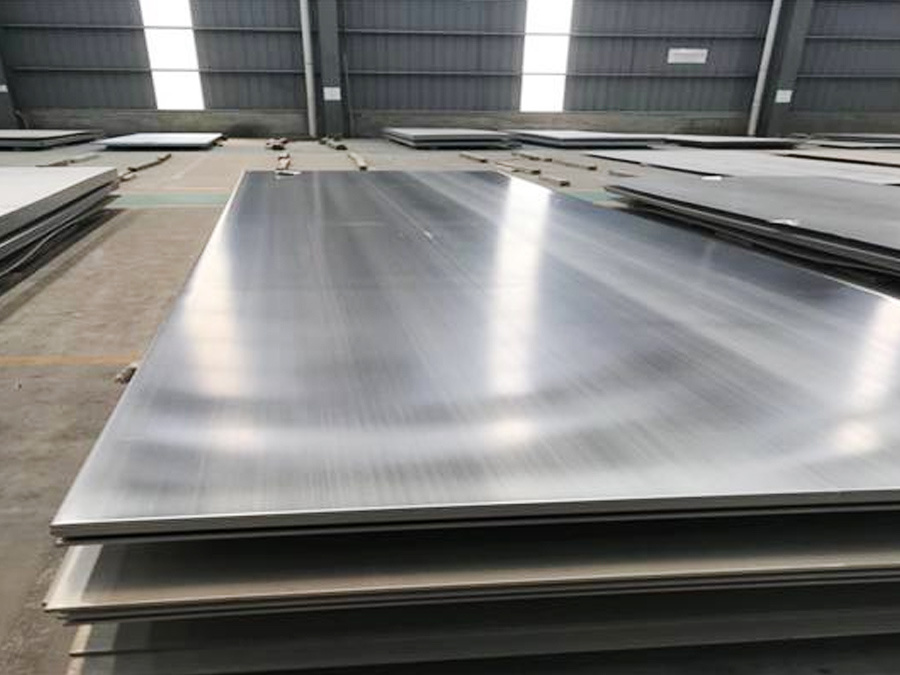

Alu-zinc, also known as galvanized aluminum, is an alloy made from a combination of aluminum and zinc. The typical composition consists of approximately 55% aluminum, 43.5% zinc, and 1.5% silicon, which together create a robust and resilient material. The unique coating process of Alu-zinc coils provides a protective layer that significantly improves the lifespan of the coated products, making them ideal for various applications.

The Benefits of Alu-zinc Coils in Industrial Equipment

1. Exceptional Corrosion Resistance

One of the most significant advantages of Alu-zinc coils is their **exceptional resistance to corrosion**. The aluminum component provides a protective layer that inhibits the onset of rust, while the zinc enhances the protective properties. This makes Alu-zinc coils particularly suitable for equipment exposed to harsh environmental conditions.

2. Enhanced Durability and Longevity

Alu-zinc coils are designed to withstand the rigors of industrial use. Their durable surface minimizes wear and tear, contributing to a longer lifespan for the equipment manufactured with these coils. Industries can benefit from reduced maintenance costs and increased operational efficiency due to the longevity of Alu-zinc products.

3. Lightweight and Strong

Another compelling factor is the combination of **lightweight properties** and strength. Alu-zinc coils are significantly lighter than traditional steel, yet they maintain superior strength characteristics. This attribute allows manufacturers to produce equipment that is easier to handle, transport, and install without compromising structural integrity.

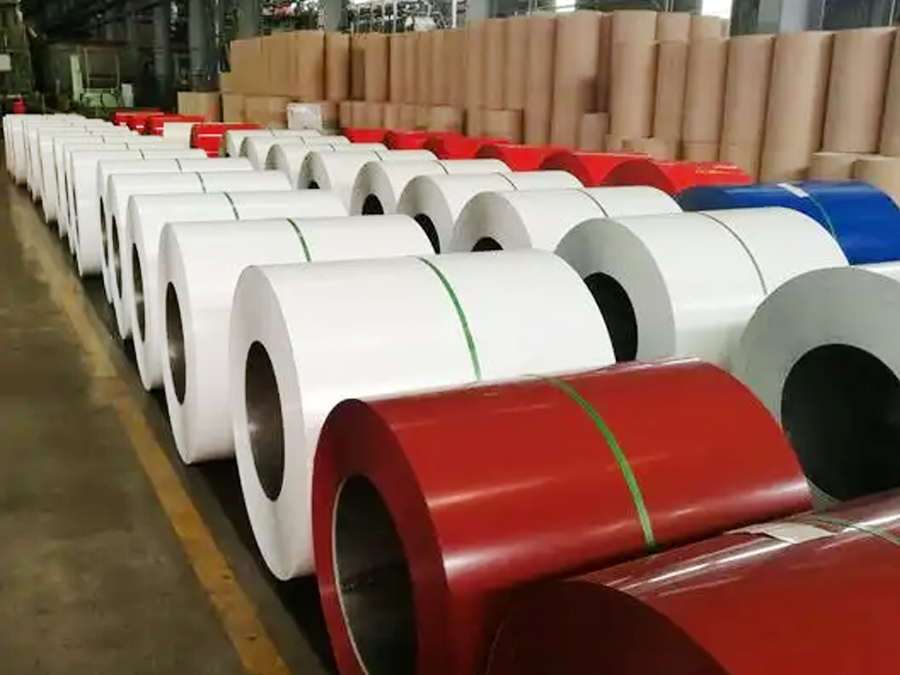

4. Aesthetic Appeal

Beyond functionality, Alu-zinc coils offer an appealing finish that enhances the visual aspect of industrial equipment. The sleek, uniform coating presents a modern look, making it suitable for applications where aesthetics matter, such as in architectural and consumer-facing industries.

Applications of Alu-zinc Coils in Industrial Equipment

1. Automotive Industry

In the automotive sector, Alu-zinc coils are increasingly used for manufacturing body panels, structural components, and chassis. Their corrosion resistance and lightweight nature contribute significantly to fuel efficiency and overall vehicle longevity.

2. Construction and Building Materials

Alu-zinc coils are prevalent in the construction industry for roofing, wall panels, and siding. The material’s durability, coupled with its resistance to environmental factors, makes it a favored choice for builders seeking reliable and long-lasting materials.

3. Home Appliances

Manufacturers of home appliances, such as refrigerators and washing machines, utilize Alu-zinc coils for their outer casings. The appealing finish and protection against rust ensure that these appliances maintain their aesthetic and functional integrity over time.

4. Electrical Equipment

In the electrical sector, Alu-zinc coils are used for producing enclosures and devices that require excellent thermal management and corrosion resistance. This is crucial for ensuring the reliability and performance of electrical installations.

5. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems benefit from Alu-zinc coils due to their resilience to moisture and thermal efficiency. The coils help enhance the performance and longevity of HVAC equipment, thereby improving energy efficiency.

How Alu-zinc Coils are Manufactured

The manufacturing process of Alu-zinc coils involves several critical steps to ensure quality and performance standards.

1. Raw Material Preparation

The process begins with the careful selection and preparation of raw materials. The aluminum and zinc are sourced from reputable suppliers, ensuring that only high-quality materials are used in the production process.

2. Coating Process

The selected steel coils are cleaned and pre-treated before undergoing the **hot-dip galvanizing process**. In this step, the steel is immersed in a molten mixture of aluminum and zinc, forming a metallurgical bond that guarantees optimal protection against corrosion.

3. Cooling and Final Treatment

Following the coating, the coils are cooled to solidify the coating layer. Additional treatments may be applied to enhance surface properties, such as lubricants or primers that improve the coils' workability during fabrication.

4. Quality Control

Quality control is paramount throughout the manufacturing process. Each batch of Alu-zinc coils undergoes rigorous testing to ensure they meet industry standards for thickness, adhesion, and corrosion resistance.

Comparing Alu-zinc with Other Coating Options

When evaluating the advantages of Alu-zinc, it’s essential to compare it with other common coating options:

1. Galvanized Steel

While both Alu-zinc and galvanized steel offer corrosion resistance, Alu-zinc coils provide superior protection due to the aluminum content. Additionally, Alu-zinc exhibits better thermal performance than traditional galvanized coatings.

2. PVC Coating

PVC coatings are often used for aesthetic purposes and additional corrosion protection, but they may not offer the same level of durability and performance as Alu-zinc coils under extreme conditions.

3. Paint Finishes

Paint finishes can enhance the appearance of products but often require regular maintenance. Alu-zinc coils, on the other hand, offer a long-lasting finish without the need for frequent repainting or touch-ups.

Environmental Benefits of Alu-zinc Coils

As industries strive for sustainability, Alu-zinc coils present several **environmental benefits**:

1. Recyclability

Alu-zinc coils are entirely recyclable at the end of their life cycle, promoting a circular economy. This aspect aligns with the increasing demand for sustainable materials in manufacturing.

2. Energy Efficiency

The lightweight nature of Alu-zinc coils contributes to energy savings during transportation and installation, reducing the overall carbon footprint associated with industrial equipment.

3. Reduced Maintenance Impact

By minimizing maintenance requirements, Alu-zinc coils help reduce waste associated with repairs and replacements, further enhancing their environmental credentials.

FAQs About Alu-zinc Coils in Industrial Equipment

1. What is the lifespan of Alu-zinc coated products?

Alu-zinc coated products can last significantly longer than traditional galvanized steel, often exceeding 25 years when properly maintained.

2. Are Alu-zinc coils suitable for outdoor applications?

Yes, Alu-zinc coils are highly resistant to outdoor conditions, making them ideal for roofing and siding applications.

3. How do Alu-zinc coils perform in high-temperature environments?

Alu-zinc coils exhibit excellent thermal stability, making them suitable for high-temperature applications, particularly in industrial settings.

4. Can Alu-zinc coils be painted or coated?

Yes, Alu-zinc coils can be painted or coated, enhancing their appearance while retaining their protective properties.

5. What industries benefit most from Alu-zinc coils?

Industries such as automotive, construction, home appliances, electrical equipment, and HVAC systems significantly benefit from Alu-zinc coils due to their unique properties.

Conclusion

In summary, Alu-zinc coils are revolutionizing the industrial equipment landscape through their exceptional properties and versatility. With benefits ranging from corrosion resistance to lightweight strength, they are set to become a staple in various industries. As we continue to push for innovation in manufacturing, Alu-zinc coils will undoubtedly play a crucial role in enhancing product longevity, sustainability, and overall performance.

Key words:

RELATED INFORMATION

How Alu-zinc Coil is Transforming Industrial Equipment

Introduction to Alu-zinc Coils and Their Industrial Significance

Alu-zinc coils have emerged as a groundbreaking material in the industrial sector, particularly in equipment manufacturing. This innovative alloy, which combines aluminum and zinc, offers remarkable resistance to corrosion, enhanced durability, and excellent thermal performance. As industries seek more efficient and long-lasting mate

2025-09-24

Understanding Corrugated Galvanized Sheets: Properties, Uses, and Benefits

Corrugated galvanized sheets, a staple in the metallurgy and energy sectors, are recognized for their durability and versatility. These sheets are made by coating steel or iron with a layer of zinc, which provides excellent corrosion resistance. The corrugated design enhances their strength while allowing for lightweight applications, making them ideal for various construction and industrial uses.

2025-09-21

Zinc Coated GI Coils: The Ultimate Solution for Enhanced Corrosion Resistance

Zinc Coated GI Coils: The Ultimate Solution for Enhanced Corrosion Resistance

Table of Contents

Introduction to Zinc Coated GI Coils

What are Zinc Coated GI Coils?

Benefits of Using Zinc Coated GI Coils

Applications of Zinc Coated GI Coils

Types of Zinc Coated GI Coils

Manufacturing Process of Zinc Coated GI Coils

Choosing the Right Supplier for Zinc Coated GI Coils

2025-09-18