Share to

Hot rolled H-beam

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

- Product Description

-

Hot rolled H-beam is a structural material widely used in construction, bridges, ships, vehicle manufacturing and other fields. Its name comes from its unique H-shaped cross-section, a design that gives H-beam a significant advantage in terms of load-bearing capacity, stability and economy.

Classification

Hot rolled H-beam specifications are divided into wide flange hot rolled H-beam specifications (HW), narrow flange hot rolled H-beam specifications (HN).

Expression

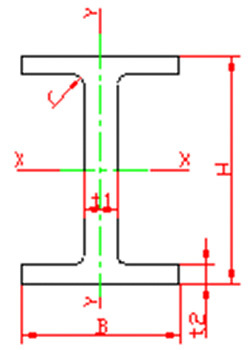

Hot rolled H-beam specifications are expressed as: height (H) width (B) web thickness (t1) wing thickness (t2), such as H-beam Q235, SS400, 200 *200 *8 * 12 expressed as 200mm high, 200mm wide, web thickness of 8mm, the wing thickness of 12mm wide flange H-beam size specifications, the grade for Q235 or SS400.

Specification

- Height: usually between 100mm and 900mm, but can be customized to meet specific needs.

- Leg width: usually between 50mm and 300mm.

- Waist thickness: ranges from 6mm to 30mm, depending on the size and use of the H-beam.

- Leg thickness: usually the same as the waist thickness or slightly thinner.

- Section area: depending on the height and waist thickness, the section area can vary from tens of square centimeters to hundreds of square centimeters.

H—height;B—width;t₁—Web thickness;t₂—Flange thickness;r—Process rounded corners

Type

Model (height*width)

Cross-section size/mm

Cross-sectional area/cm²

H×B

t₁

t₂

r

HW

Wide flange

100×100

100×100

6

8

10

21.90

125×125

125×125

6.5

9

10

30.31

150×150

150×150

7

10

13

40.55

175×175

175×175

7.5

11

13

51.43

200×200

200×200

8

12

16

64.28

200×204

12

12

16

72.28

250×250

250×250

9

14

16

92.18

250×255

14

14

16

104.7

300×300

294×302

12

12

20

108.3

300×300

10

15

20

120.4

300×305

15

15

20

135.4

350×350

344×348

10

16

20

146.0

350×350

12

19

20

173.9

400×400

388×402

15

15

24

179.2

394×398

11

18

24

187.6

400×400

13

21

24

219.5

400×408

21

21

24

251.5

414×405

18

28

24

296.2

428×407

20

35

24

361.4

458×417

30

50

24

529.3

498×432

45

70

24

770.8

Type

Model (height*width)

Cross-section size/mm

Cross-sectional area/cm²

H×B

t₁

t₂

r

HM

Middle flange

150×100

148×100

6

9

13

27.25

200×150

194×150

6

9

16

39.76

250×175

244×175

7

11

16

56.24

300×200

294×200

8

12

20

73.03

350×250

340×250

9

14

20

101.5

400×300

390×300

10

16

24

136.7

450×300

440×300

11

18

24

157.4

500×300

482×300

11

15

28

146.4

488×300

11

18

28

164.4

600×300

582×300

12

17

28

174.5

588×300

12

20

28

192.5

594×302

14

23

28

222.4

Type

Model (height*width)

Cross-section size/mm

Cross-sectional area/cm²

H×B

t₁

t₂

r

HN

Narrow flange

100×50

100×50

5

7

10

12.16

125×60

125×60

6

8

10

17.01

150×75

150×75

5

7

10

18.16

175×90

175×90

5

8

10

23.21

200×100

198×99

4.5

7

13

23.59

200×100

5.5

8

13

27.57

250×125

248×124

5

8

13

32.89

250×125

6

9

13

37.87

300×150

298×149

5.5

8

16

41.55

300×150

6.5

9

16

47.53

350×175

346×174

6

9

16

53.19

350×175

7

11

16

63.66

400×150

400×150

8

13

16

71.12

400×200

396×199

7

11

16

72.16

400×200

8

13

16

84.12

450×150

450×150

9

14

20

83.41

450×200

446×199

8

12

20

84.95

150×200

9

14

20

97.41

500×150

500×200

10

16

20

98.23

500×200

496×199

9

14

20

101.3

500×200

10

16

20

114.2

506×201

11

19

20

131.3

600×200

596×199

10

15

24

121.2

600×200

11

17

24

135.2

606×201

12

20

24

153.3

700×300

692×300

13

20

28

211.5

700×300

13

24

28

235.5

800×300

792×300

14

22

28

243.4

800×300

14

26

28

267.4

900×300

890×299

15

23

28

270.9

900×300

16

28

28

309.8

912×302

18

34

28

364.0

Material

- Q235: an ordinary carbon structural steel with good comprehensive mechanical properties and welding performance.

- Q345: a kind of low alloy high-strength structural steel with higher strength, which is suitable for structures with larger loads.

- Q420: a high-strength structural steel with higher strength and better corrosion resistance.

- Other special materials: other special materials of steel can be used according to specific engineering requirements.

Process

Opening, roughing, finishing, cooling, straightening, sawing and inspection.

Applications

- Building structures: such as high-rise buildings, industrial plants, warehouses, gymnasiums and so on.

- Bridge engineering: used for main girders and piers of bridges, etc.

- Shipbuilding: as the skeleton material of ships.

- Machinery Manufacturing: Used in the manufacture of various mechanical equipment support structure.

- Transportation facilities: such as guardrail supports for highways, railroad bridges, etc.

Advantage

- High strength and light weight: the cross-section design of H-beam makes it light weight while maintaining high strength, which is conducive to reducing transportation and installation costs.

- Good stability: the wide flange design of H-beams provides good bending and torsion resistance, making them suitable for large-span structures.

- Material saving: due to its efficient material utilization, H-beam can reduce the use of materials and lower the project cost.

- Convenient construction: the standardization and serialization of H-beam makes the construction process more convenient and faster.

- Good durability: Hot rolled H steel has good corrosion resistance and is suitable for a wide range of environmental conditions.

- Recyclable: steel is a recyclable material, which meets the requirements of sustainable development.

Hot rolled H-beam

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Hot rolled H-shaped steel

Welding H-shaped steel

Wide flange H-shape steel

Narrow flange H-shape steel

Building steel structural support

Bridge support

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products