Share to

Strip Steel

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

View similar products

- Product Description

-

Thin, narrow and long steel plate.

Strip steel, also known as steel strip, refers to a strip of steel with a certain width and extremely long length, mostly rolled into a roll. The width is greater than 600 mm for wide strips, and the width is less than 600 mm for narrow strips. Strip steel has various specifications. At present, the width of the strip steel operated by our company is 20-1000mm and the thickness is 0.05-6.0mm. The main materials are Q195 Q235 Q355 Q215, etc.:

According to the quality of steel is divided into high quality and ordinary strip steel;

According to the rolling method is divided into hot rolled steel strip and cold rolled steel strip,

Specifications

Material

carbon steel, carbon bonded steel, spring steel, tool steel, and other steel production

Grade

Q195 Q235 Q355 Q215 SS400 SPHC sae006 sae008 SPHD

Standard

bs EN GB AiSi ASTM DIN JIS

Width:

20mm-1000mm

Thickness

hot rolled ordinary strip thickness of 2mm-6mm,

cold rolled strip is generally 0.05mm - 3.60mm.

Weight:

3-5tons

MOQ

28tons

Delivery Time

20days

Packaging:

Packing belt,binding

Process

Cold rolled strip process:

pickling -- rolling -- annealing -- synchronous lubrication of rolling size -- anti-rust oil -- leveling and sizing -- polishing -- packaging

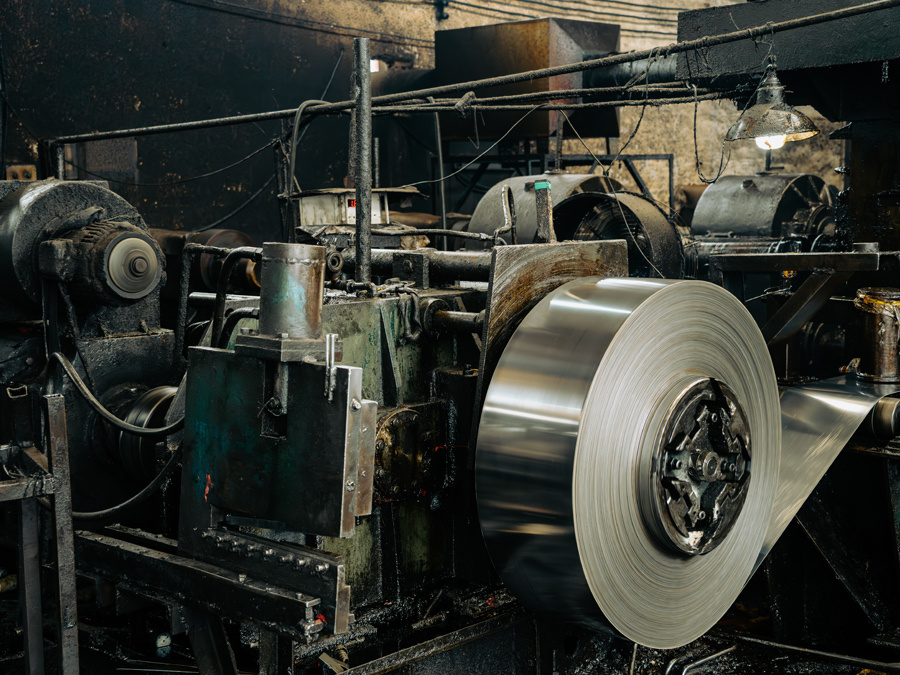

Hot rolled strip process:

Heating furnace - phosphorus removal machine - roughing mill - phosphorus removal machine - finishing mill - Surface quality inspection instrument layer cold - coiler - bundling machine - spray mark machine - coil store slab

First, the temperature in the heating furnace is raised to the required rolling temperature, and then through the roller table into the rough rolling phosphorus removal machine to treat the oxide sheet produced by the slab.

Then the width and thickness of the strip are rolled in the rough rolling mill, and the oxidized iron sheet produced on the surface of the strip is processed by the finishing rolling mill, and the thickness and width of the strip are rolled in the finishing rolling mill, and the surface temperature of the strip is strictly controlled before being rolled by the roller table through layer cooling.

Enter the coiler to become the final steel coil bundling, spray number into the coil inventory for packaging.

Advantages: strip steel is generally supplied in coils, with high dimensional accuracy, good surface quality, easy processing, material saving and other advantages.

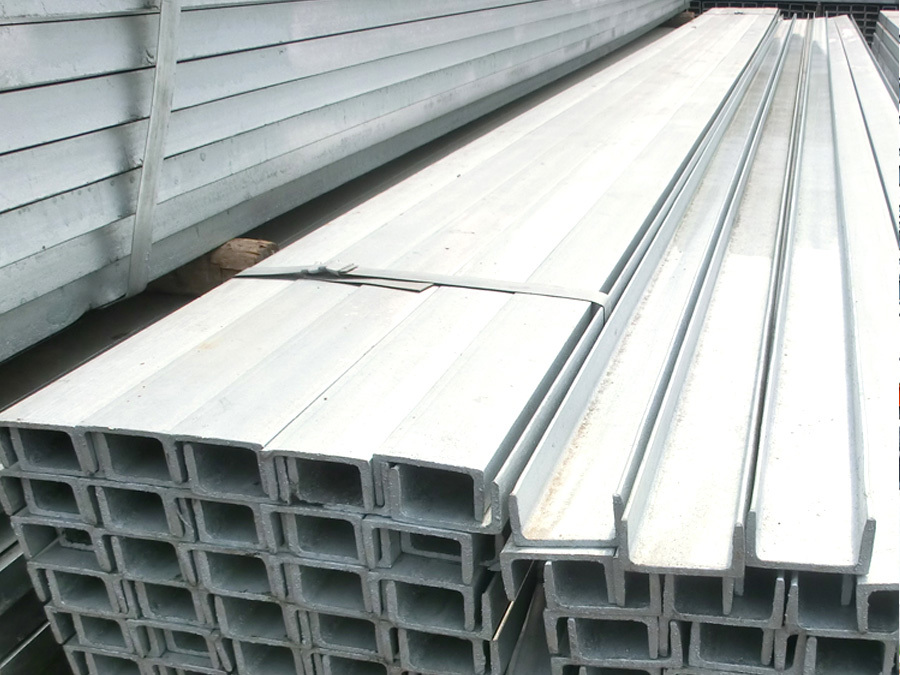

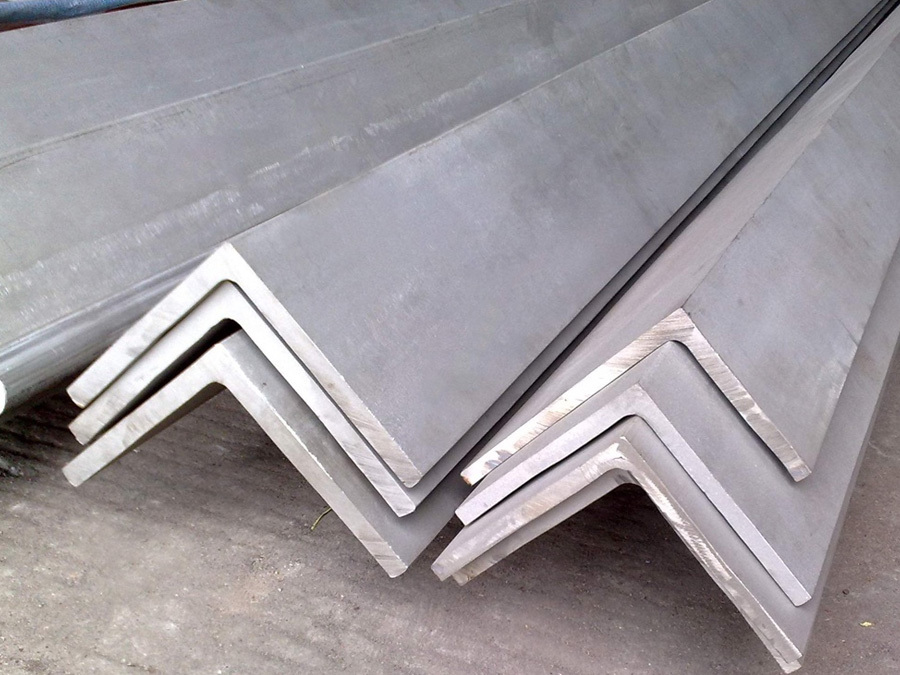

Product photos

Strip Steel

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Steel strip

Galvanized steel strip

Spring steel strip

Steel strip coil

Cold rolled steel strips

Carbon steel strip

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products