Share to

Zinc-Aluminum-Magnesium Steel Coil

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Description

-

Zinc-Aluminum-Magnesium Steel Coil is a kind of alloy coil composed of zinc, aluminum, magnesium and other metal elements, which is mainly used for the surface anti-corrosion treatment of steel and steel products. Its main components include zinc, aluminum and magnesium, with the magnesium content usually ranging from 1.0 to 2.0% and the aluminum content ranging from 0.8 to 3.0%.

Specification

Material

Cold rolled steel sheet, dot-dip galvanized steel sheet, aluminum sheet, Magnesium alloy sheet.

Standard

JIS/ASTM/EN

Grade

DX51D+ZM, DX52D+ZM, DX53D+ZM, S220GD + ZM,HD300LAD + ZM/HD340LAD + ZM/HD380LAD + ZM,SGMCC + ZM/SGHCD + ZM/SGH340D + ZM/SGH400D + ZM/SGH540D + ZM

Thickness

0.8-4.5mm

Width

750-1600mm

ZM Coating

ZM20-ZM600g/㎡

Spangle

Zero Spangle, Regular Spangle

Inner Diameter

508/610mm

Coil Weight

3-4tons, 4-6tons, 3-8tons or according to customer requirements

MOQ

36 tons

Delivery Time

about 35 days

Package

Standard export package

Applications

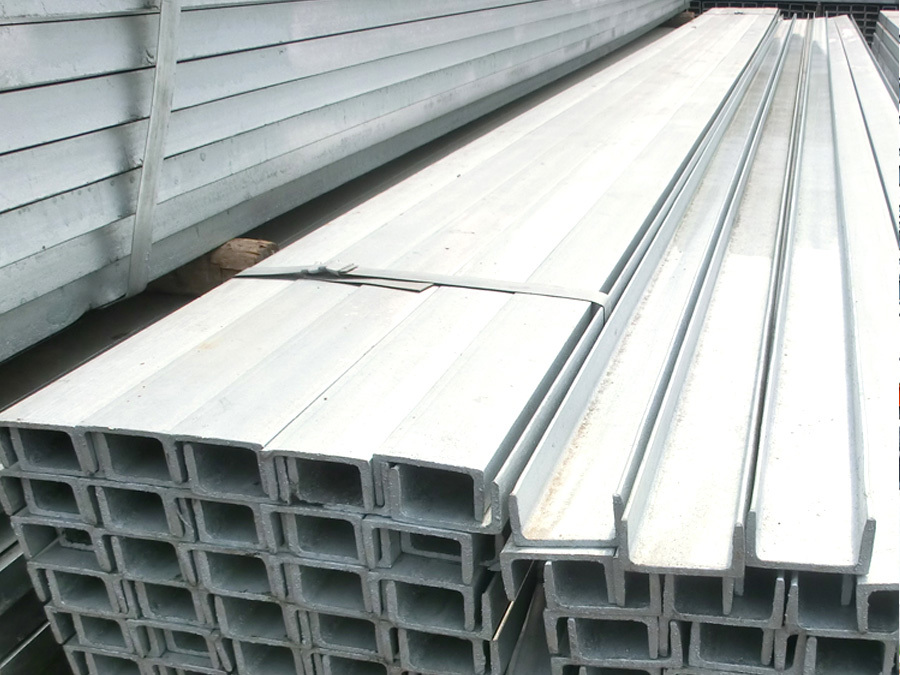

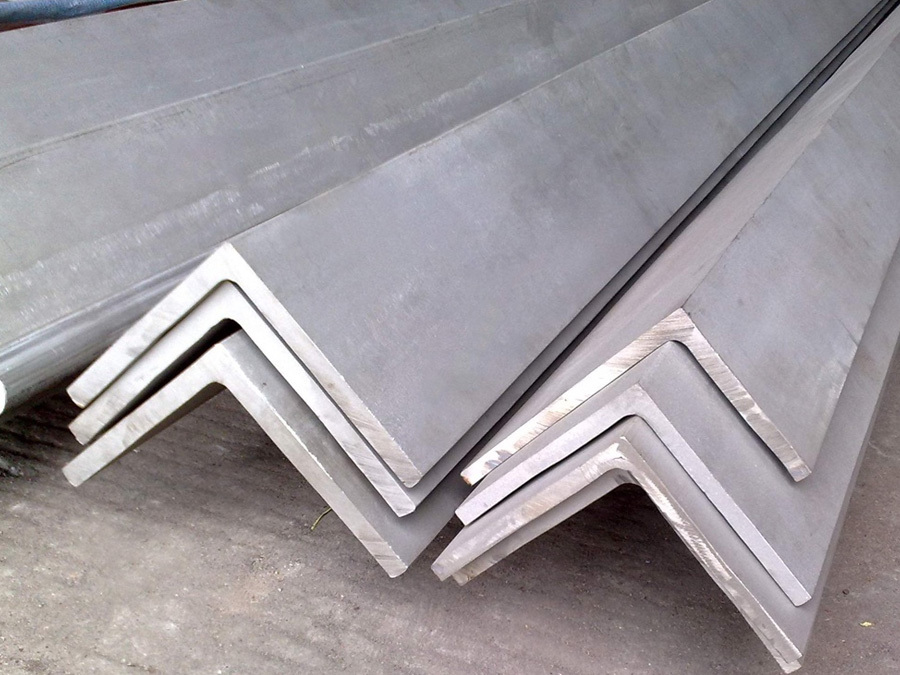

1. Construction field

Zinc-aluminum-magnesium coil has excellent corrosion resistance and can be used for a long time in harsh climatic environments. Therefore, it is commonly used in the construction industry for roofing, walling, eaves, chimneys, rainwater pipes and so on.

2. Automobile manufacturing

Zinc-aluminum-magnesium coil sheet has good mechanical properties, wear resistance, corrosion resistance, good shock resistance and plasticity, especially suitable for automobile parts manufacturing. Nowadays, more and more automobile enterprises choose to use Zinc aluminum magnesium coil to produce body components, in order to improve the durability and safety of automobiles.

3. Appliance manufacturing

Due to the good corrosion resistance, high strength, light weight and other characteristics of Zinc aluminum magnesium coil, gradually become one of the important materials for the home appliance industry. Home appliance industry applications are more washing machine shell, refrigerator shell, water heater shell, oven shell and so on.

4. Electrical equipment

Zinc-aluminum-magnesium coil plate has good electrical conductivity and can be used in the manufacture of electrical equipment, such as power distribution devices, power generation equipment, transformers, electrical connections and so on.

Advantages

1. High corrosion resistance

Zinc-aluminum-magnesium coil has very excellent corrosion resistance and can be used in most harmful environments to prevent oxidation and corrosion, which improves the service life of the product.

2. Good mechanical properties

Zinc aluminum magnesium coil has good mechanical properties, high strength, hardness, wear resistance, fatigue resistance, able to withstand high strength pressure and heavy load impact.

3. Light weight

Zinc-aluminum-magnesium coil is light in specific gravity and light in weight, which can effectively reduce the self-weight of the product, facilitate handling and installation, and reduce the transportation cost.

4. Good plasticity

Zinc-aluminum-magnesium coil plate has good plasticity and is easy to be processed into various shapes to meet the needs of manufacturing various products.

Process

1. Preparation of raw materials

The production of zinc-aluminum-magnesium coil mainly requires some basic raw materials, such as cold rolled sheet, hot dipped galvanized steel sheet, aluminum sheet, magnesium alloy sheet and so on. Among them, magnesium alloy plate is one of the main components of zinc-aluminum-magnesium coil, usually made of magnesium with high purity mixed with aluminum alloy.

2. Hot-dip galvanized

Hot dip galvanizing belongs to the zinc-aluminum-magnesium coil production is an important link, but also the basic link of zinc-aluminum-magnesium coil. First of all, it is necessary to cold rolled steel plate through the de-oiling, alkali washing and other treatments, in order to remove the surface oil, oxides and other impurities. Subsequently, using the hot dip galvanizing process, the steel plate is dipped in a zinc solution to form a zinc cover layer on the surface. This process can effectively protect the surface of zinc-aluminum-magnesium coil, improve its corrosion resistance and service life.

3. Coating

Coating is one of the key links in the production process of zinc-aluminum-magnesium coil. In the hot dip galvanizing, need to be coated to enhance the surface of the steel plate weathering and corrosion resistance. Coating is usually done by spraying technology, in which the coating is evenly sprayed on the surface of the steel plate and cured by drying and other means. The thickness and type of coating is also one of the important factors affecting the quality of zinc aluminum magnesium coil.

4. Drying

After coating zinc aluminum magnesium coil needs to be dried to ensure the quality and performance of the coating. Drying is generally divided into two stages, the first is the initial drying, that is, the coating is heated to a certain temperature, so that it volatilizes water; and then stereotypes drying, that is, the steel plate is heated, and a certain period of time drying, in order to make the coating curing.

5. Cold rolling

Zinc aluminum magnesium coil after coating and drying, need to be cold rolled in order to make it become steel coil or steel plate and other finished products. Cold rolling mainly use pressure rolls to carry out the surface of the steel plate shaping and processing, which also need to be curled, straightening and other processes, in order to overcome the steel plate in the production process to produce the phenomenon of unshaped.

6. Shear

Finally, the production of zinc-aluminum-magnesium coil needs to be sheared to cut it into the appropriate size and shape. Shearing is generally carried out using steel knives, while the need for appropriate adjustments to the shear to ensure that the quality of the shear.

Applications

Packaging diagram

Zinc-Aluminum-Magnesium Steel Coil

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Zinc Aluminum Magnesium steel coil

Prepainted Zn-Al-Mg steel coil

Zn-Al-Mg coating steel coil

Zinc Aluminum Magnesium roofing sheet coils

Zn-Al-Mg alloy coating steel coil

Zn-Al-Mg Coating plate coils

customized Zn-Al-Mg coating steel coil

Aluzinc Steel Coil china

Zn-Al-Mg Coating Steel Coil

Zinc Coated Gi Coil

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products