Share to

Color coated steel roofing sheet

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

- Product Description

-

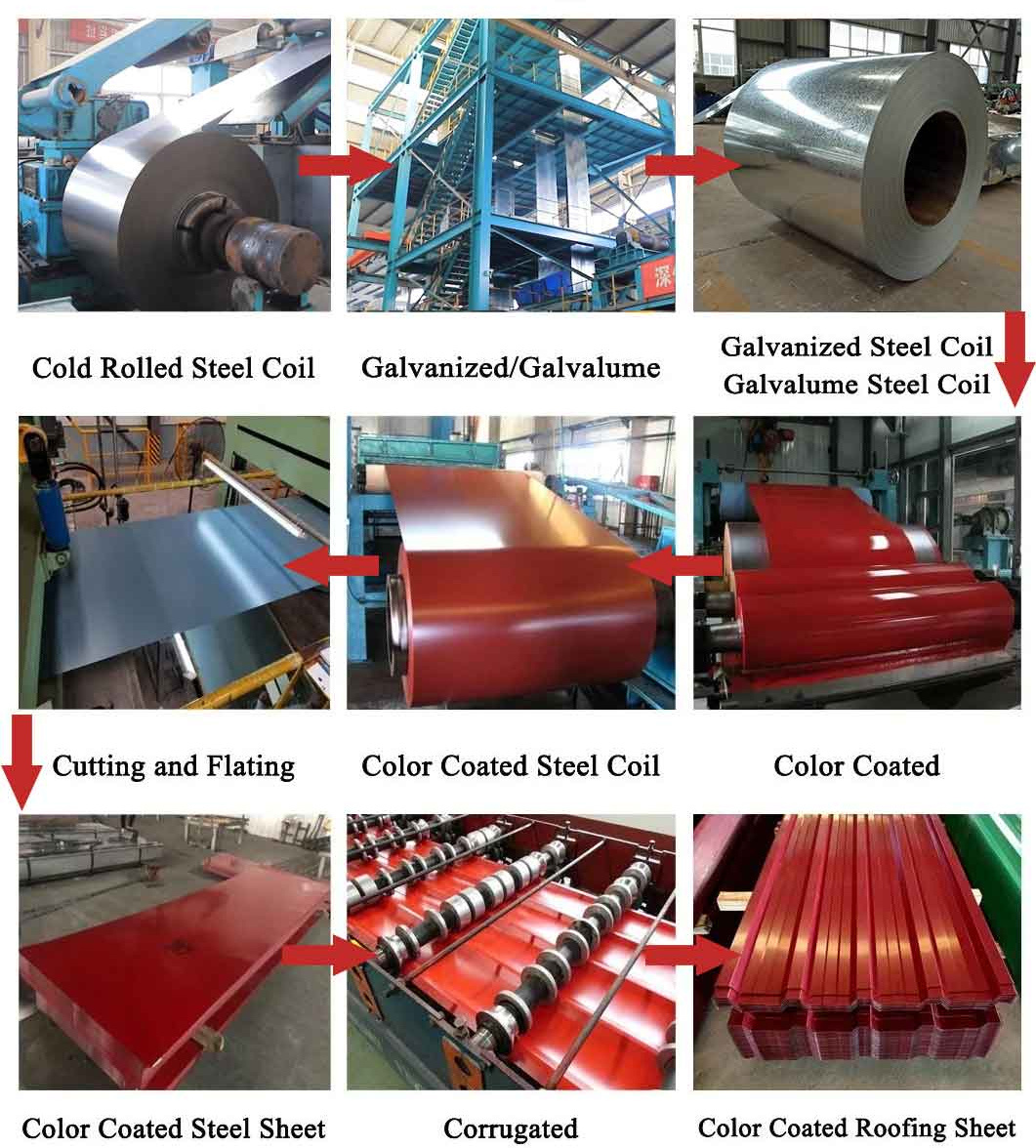

Color coated corrugated steel sheet consists of two parts: the substrate and the coating. The substrate is usually cold-rolled steel, galvanized steel or aluminium-zinc plated steel.

Galvanized steel is coated with a layer of zinc on the surface of the steel plate, which has good anti-corrosion properties.

Aluminium-zinc plated steel is coated with an alloy of aluminium and zinc on the surface of the steel plate, which has better anti-corrosion properties than galvanized steel.

Cold rolled steel plate does not have this coating, but its strength properties are better.

Specification

Material

Standard

Grade

Paint Film

Color

Cold rolled steel sheet, Hot-dip galvanized steel sheet, electro galvanized steel sheet, hot-dip galvalume steel sheet, etc

ASTM A755/A755M、EN 10169、JIS G 3312, etc

SGCC,SGCH,G550,DX51D,DX52D,DX53D,etc

Right side15-35microns,Reverse side5-10microns

RAL Color(Red,Green,Blue,Yellow,etc)

Thickness

Width

Length

Package

MOQ

Delivery time

0.12-1.2mm

608-1050mm

6meters, customized

Standard sea transport package

25MT

15-20days

Applications

Color coated corrugated sheet is suitable for industrial and civil buildings, warehouses, special buildings, large-span steel structure housing roof, wall and internal and external wall decoration, etc. It has the characteristics of light weight, high strength, rich colour and lustre, convenient and quick construction, anti-seismic, fireproof, rainproof, long life, maintenance-free, etc., and has been widely promoted and applied.

Material of pigment

The coatings are mainly organic and are generally made of polyester (PE), silicone-modified polyester (SMP), highly durable polyester (HDP) or polyvinylidene fluoride (PVDF). This gives the steel sheets a wide range of colours and varying degrees of weathering, corrosion and stain resistance. For example, PVDF-coated coloured steel sheets have excellent weathering resistance and are able to maintain stable colour and performance for long periods of time in harsh outdoor environments.

Type of coating structure

2/1: Coat the top surface of the steel sheet twice, coat the back surface once, and bake the sheet twice.

2/1M: Coat and bake twice for both top surface and back surface.

2/2: Coat the top/back surface twice and bake twice.

Advantages

1. Rich in colour: colour steel plate comes in a variety of colours, which can be chosen according to different architectural styles and uses.

2. Light weight and high strength: colour steel plate is light in weight, which is easy to transport and install. At the same time, it has high strength and can withstand certain wind pressure, snow pressure and other loads.

3. Good waterproof: due to the sealing of its surface coating and the structural characteristics of the steel plate itself, colour steel plate has good waterproof performance. In the application of building roofing, it can effectively prevent rainwater seepage and ensure the dryness of the building interior.

4. Thermal insulation performance: if there are thermal insulation materials, such as polystyrene foam (EPS), polyurethane foam (PU), etc., sandwiched in the middle of the colour steel plate, a composite plate with good thermal insulation performance can be formed.

5. Good corrosion resistance: thanks to the plating of the substrate and the organic coating on the surface, the colour steel plate is able to resist the corrosive medium in the atmosphere, such as acid rain and salt spray.

Process

1. Selection of base plate

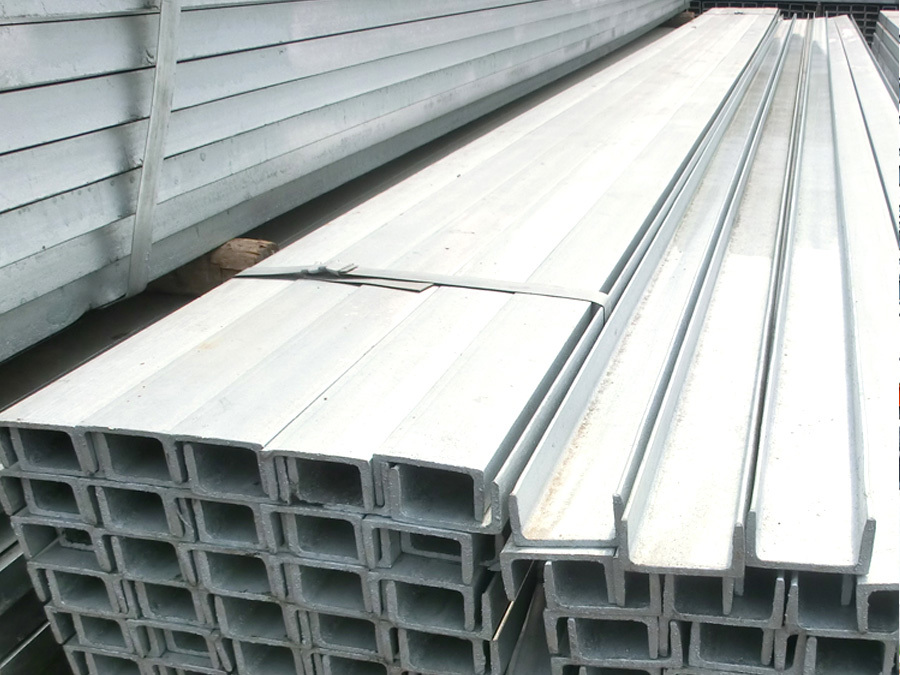

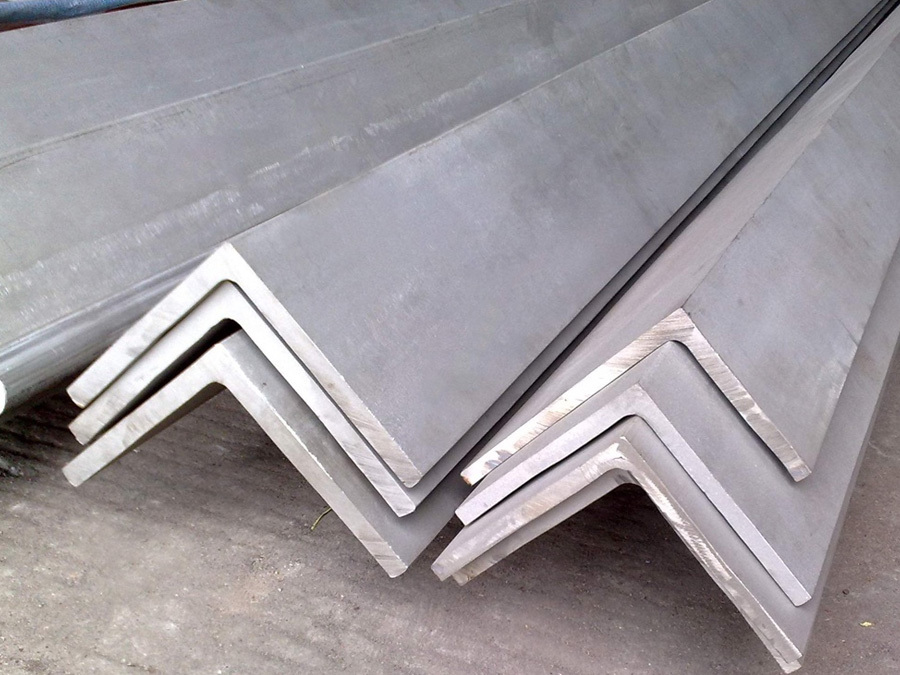

The substrates of color coated steel sheet mainly include cold rolled steel plate and galvanized plate. When selecting the substrate, it is necessary to consider its performance characteristics, thickness, flatness and other factors to ensure the quality and use of color coated steel sheet.

2. Surface treatment

Firstly, the surface treatment of the substrate is carried out in order to prepare for the next step of coating. The process of surface treatment includes degreasing, acid washing, alkaline washing, phosphoric acid treatment and other processes. These processes can effectively remove impurities such as dirt and iron oxide on the surface of the substrate, and at the same time improve the adhesion and corrosion resistance of the substrate surface.

3. Coating Production

After surface treatment, the substrate is fed into the coating line for coating. The coating production process includes three parts: primer, top coating and varnish.

4. Curing

After the coating is completed, the coils are baked and cured. In the baking curing process, the color coated steel coil is fed into a high-temperature oven, and different temperatures and times are set according to the selected materials. Through curing, the coating materials can be fully reacted and cross-linked, thus improving the performance indexes of the color coated steel coil such as weather resistance, hardness and adhesion.

5.Steel plate pressed tile

When the substrate passes through the rolls, under the pressure of the rolls, the substrate is continuously cold-formed into wavy corrugated shapes.

6.Cutting and packaging

According to the requirements of customers or the standard dimensions of products, the formed corrugated sheets are cut. The cutting can be carried out by using mechanical cutting equipment, such as plate shears, or by adopting numerical control cutting technology.

Packaging diagram

Application scenario diagram

Flow chart

Color coated steel roofing sheet is a high-performance building material designed for roofing applications, fabricated by applying specialized organic coatings to the surface of galvanized or aluminized steel substrates. This product combines the structural strength of steel with the aesthetic appeal and protective properties of advanced coatings, making it a preferred choice for residential, commercial, and industrial buildings worldwide.

One of its core advantages is exceptional corrosion resistance. The zinc or aluminum base layer acts as a barrier against rust, while the top coating (commonly PVDF, PE, or SMP) further enhances resistance to moisture, salt spray, and industrial pollutants—ensuring the roofing sheet maintains structural integrity even in harsh environments like coastal areas or industrial zones, with a service life of 15-25 years. Another key feature is long-lasting color retention: the high-quality coatings undergo strict weather resistance testing, resisting fading, chalking, and discoloration caused by UV radiation, extreme temperatures, and heavy rainfall, thus preserving the building’s exterior aesthetics for decades.

In terms of installation and adaptability, color coated steel roofing sheet offers significant advantages. It is lightweight (typically 5-8 kg/m²), reducing the load on building structures compared to traditional materials like concrete tiles or clay shingles. Its flexible design allows it to be cut, bent, and formed into various profiles (e.g., trapezoidal, corrugated) to fit different roof slopes and architectural styles, while the interlocking installation system enables quick and efficient construction—shortening project timelines and lowering labor costs.

Environmentally, this roofing sheet aligns with green building standards. The steel substrate is 100% recyclable, and the coatings are formulated with low VOC (volatile organic compound) content, minimizing environmental impact during production and disposal. Additionally, its smooth surface reduces heat absorption, contributing to better building energy efficiency by lowering indoor cooling demands in summer.

Whether used for residential villas, commercial malls, or industrial warehouses, color coated steel roofing sheet balances durability, aesthetics, and cost-effectiveness—providing building owners with a low-maintenance, long-term roofing solution that enhances both functionality and property value.

Color coated steel roofing sheet

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Color steel roofing sheet

Prepainted steel roofing sheet

PPGI steel roofing sheet

PPGL steel roofing sheet

Corrugated color coated steel sheet

Trapezoidal prepainted steel plate

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products