Zinc Coated GI Coils: The Ultimate Solution for Enhanced Corrosion Resistance

2025-09-18

Zinc Coated GI Coils: The Ultimate Solution for Enhanced Corrosion Resistance

Table of Contents

Introduction to Zinc Coated GI Coils

What are Zinc Coated GI Coils?

Benefits of Using Zinc Coated GI Coils

Applications of Zinc Coated GI Coils

Types of Zinc Coated GI Coils

Manufacturing Process of Zinc Coated GI Coils

Choosing the Right Supplier for Zinc Coated GI Coils

Zinc Coated GI Coils: The Ultimate Solution for Enhanced Corrosion Resistance

Table of Contents

- Introduction to Zinc Coated GI Coils

- What are Zinc Coated GI Coils?

- Benefits of Using Zinc Coated GI Coils

- Applications of Zinc Coated GI Coils

- Types of Zinc Coated GI Coils

- Manufacturing Process of Zinc Coated GI Coils

- Choosing the Right Supplier for Zinc Coated GI Coils

- Frequently Asked Questions

- Conclusion

Introduction to Zinc Coated GI Coils

Zinc-coated galvanized iron (GI) coils are renowned for their exceptional **corrosion resistance** and durability, making them a vital component in various industries. These coils are not only versatile but also vital in protecting structures from the adverse effects of corrosion, particularly in harsh environments. As industry demands evolve, understanding the intricacies of zinc-coated GI coils becomes imperative for architects, engineers, and manufacturers alike.

What are Zinc Coated GI Coils?

Zinc-coated GI coils are sheets made from iron that are coated with a layer of zinc to enhance their **corrosion resistance**. The process of galvanization involves applying a protective zinc coating to the iron substrate, which serves as a barrier against moisture, oxygen, and other corrosive agents. This protective layer ensures that the underlying iron remains intact, providing a longer service life and reducing maintenance costs.

The Importance of Corrosion Resistance

Corrosion can significantly compromise the strength and stability of metal structures. Zinc coating acts as a sacrificial layer, where zinc oxidizes preferentially to iron. This unique property allows the iron to remain protected even if the coating is scratched, making zinc-coated GI coils an excellent choice for a wide range of applications.

Benefits of Using Zinc Coated GI Coils

The advantages of zinc-coated GI coils extend far beyond mere corrosion resistance. Their unique properties offer a multitude of benefits, including:

1. Longevity and Durability

Zinc-coated GI coils can last for decades, significantly reducing the frequency of replacements. Their resilience against environmental factors such as rain, humidity, and temperature fluctuations ensures a long-lasting solution for construction and manufacturing needs.

2. Cost-Effectiveness

While the initial investment may be higher than non-coated alternatives, the long-term savings from reduced maintenance and replacement costs make zinc-coated GI coils a cost-effective choice for various projects.

3. Versatility in Applications

These coils can be used in a wide array of applications, from roofing to automotive components, making them a versatile choice in the industry.

4. Aesthetic Appeal

Zinc-coated coils have a clean and attractive finish, making them suitable for architectural applications where appearance is important. They can also be painted or coated further to enhance their appearance and protection.

5. Environmental Benefits

The longevity and recyclability of zinc-coated GI coils contribute to their environmental sustainability, helping industries adhere to eco-friendly practices.

Applications of Zinc Coated GI Coils

Zinc-coated GI coils find applications across various sectors due to their superior properties. Key applications include:

1. Construction

In construction, zinc-coated GI coils are widely used for roofing, siding, and structural components, providing reliable protection against weather elements.

2. Automotive

The automotive industry uses these coils for manufacturing body parts, chassis components, and other structural elements that require resistance to corrosion.

3. Electrical Appliances

Zinc-coated GI coils are used in electrical appliances for housings, frames, and other components that need protection against rust and corrosion.

4. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems benefit from zinc-coated coils due to their ability to withstand moisture and humid environments.

5. Furniture and Fixtures

The furniture industry utilizes these coils for various fixtures, ensuring a durable and aesthetically pleasing finish.

Types of Zinc Coated GI Coils

Understanding the different types of zinc-coated GI coils is crucial for selecting the right product for specific applications. The primary types include:

1. Hot-Dip Galvanized Coils

These coils are coated by dipping them into molten zinc, providing a thick and robust layer of protection. This method is highly effective for outdoor applications.

2. Electro-Galvanized Coils

In electro-galvanization, a thin layer of zinc is applied using an electric current. These coils offer a smoother finish and are ideal for applications where aesthetics are critical.

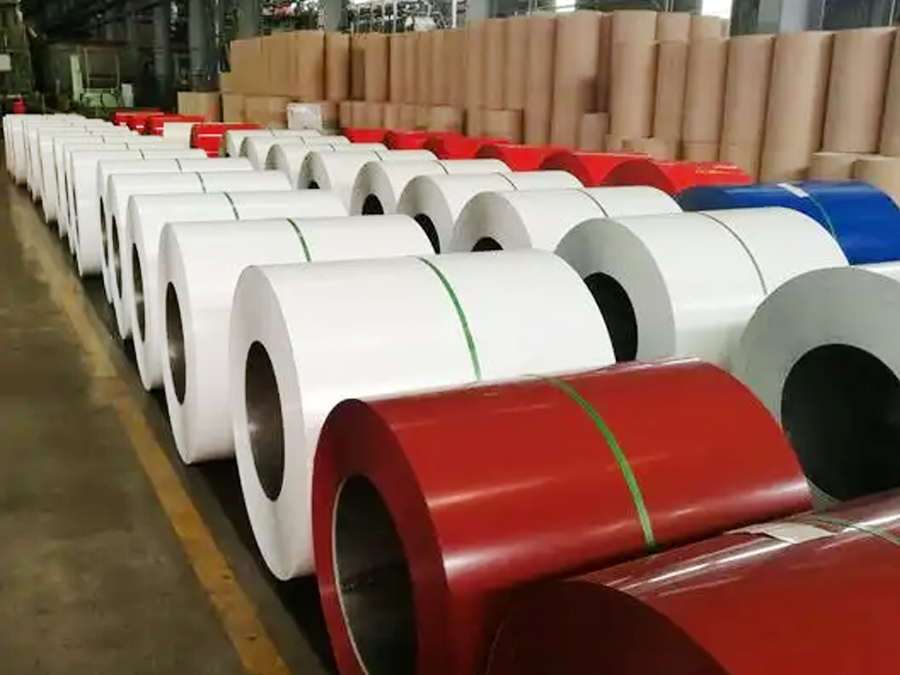

3. Pre-Painted Zinc Coated Coils

These coils come with a pre-applied paint layer, offering additional protection and aesthetic appeal. Pre-painted options save time and provide a ready-to-use solution for manufacturers.

Manufacturing Process of Zinc Coated GI Coils

The manufacturing of zinc-coated GI coils involves several critical steps:

1. Preparation of the Base Material

The base iron or steel is cleaned to remove impurities that could hinder the bonding of zinc.

2. Galvanization

The cleaned coils are either hot-dipped or electro-galvanized to apply the zinc coating.

3. Cooling and Inspection

After galvanization, the coils are cooled and inspected for consistency in coating thickness and quality.

4. Finishing

Once inspected, the coils may undergo additional processes such as painting or surface treatment before being packaged for shipment.

Choosing the Right Supplier for Zinc Coated GI Coils

Selecting a reputable supplier is crucial for ensuring the quality of zinc-coated GI coils. Consider the following factors:

1. Quality Standards

Ensure that the supplier adheres to industry standards and certifications for galvanization quality.

2. Range of Products

Look for suppliers offering a diverse range of coils to meet various application needs.

3. Customer Support

A reliable supplier should provide excellent customer service, including technical support and efficient order processing.

4. Pricing and Availability

Compare prices and assess the availability of products to ensure timely delivery without compromising quality.

Frequently Asked Questions

1. What is the lifespan of zinc-coated GI coils?

The lifespan can vary significantly based on environmental conditions but generally ranges from 10 to 50 years.

2. Can zinc-coated GI coils be used outdoors?

Yes, they are specifically designed for outdoor applications due to their corrosion resistance.

3. How do I maintain zinc-coated GI coils?

Regular inspections and cleaning can help maintain their integrity. Avoid using harsh chemicals that could damage the zinc coating.

4. Are zinc-coated GI coils recyclable?

Yes, they are fully recyclable, making them an eco-friendly option.

5. How do I choose the right type of zinc-coated coil?

Consider the specific application requirements, including exposure to corrosive environments and aesthetic needs.

Conclusion

Zinc-coated GI coils stand out as a superior choice for industry professionals seeking long-lasting, cost-effective solutions for corrosion resistance. Their extensive range of applications, combined with the numerous benefits they offer, makes them ideal for construction, automotive, HVAC systems, and more. By understanding their properties, types, and manufacturing processes, industries can harness the full potential of zinc-coated GI coils, ensuring durability and sustainability in their projects. As we move towards a more eco-conscious future, choosing zinc-coated solutions will prove vital for enhancing structural integrity while minimizing environmental impact.

Key words:

RELATED INFORMATION

Zinc Coated GI Coils: The Ultimate Solution for Enhanced Corrosion Resistance

Zinc Coated GI Coils: The Ultimate Solution for Enhanced Corrosion Resistance

Table of Contents

Introduction to Zinc Coated GI Coils

What are Zinc Coated GI Coils?

Benefits of Using Zinc Coated GI Coils

Applications of Zinc Coated GI Coils

Types of Zinc Coated GI Coils

Manufacturing Process of Zinc Coated GI Coils

Choosing the Right Supplier for Zinc Coated GI Coils

2025-09-18

Understanding Prepainted Roofing Sheets: Features, Benefits, and Applications

Prepainted roofing sheets, often referred to as color-coated sheets, are metal sheets coated with a layer of paint before they are formed into roofing products. This pre-coating process not only enhances the visual appeal of the roofing material but also provides an extra layer of protection against environmental factors. Typically, these sheets are made from various metals, including galvanized s

2025-09-15

The Environmental Impact of Using Zn-Al-Mg Coated Steel Coil in Construction

The Environmental Impact of Using Zn-Al-Mg Coated Steel Coil in Construction

Table of Contents

Introduction to Zn-Al-Mg Coated Steel Coil

The Importance of Materials in Sustainable Construction

Understanding the Composition of Zn-Al-Mg Coated Steel

Benefits of Using Zn-Al-Mg Coated Steel Coil

1. Durability and Longevity

2. Corrosion Resistance

2025-09-12