Understanding Corrugated Galvanized Sheets: Properties, Uses, and Benefits

2025-09-21

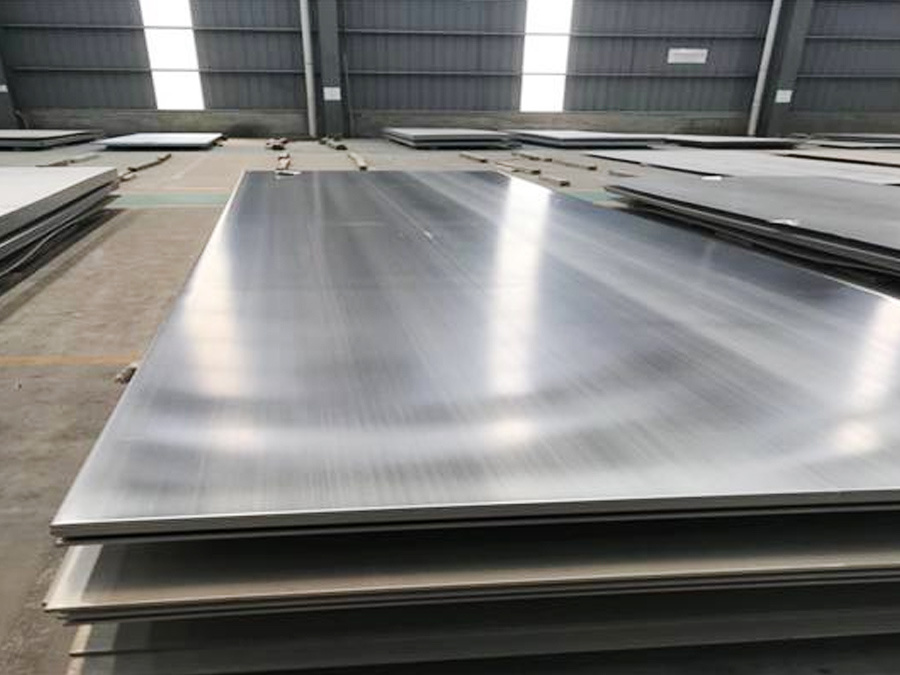

Corrugated galvanized sheets, a staple in the metallurgy and energy sectors, are recognized for their durability and versatility. These sheets are made by coating steel or iron with a layer of zinc, which provides excellent corrosion resistance. The corrugated design enhances their strength while allowing for lightweight applications, making them ideal for various construction and industrial uses.

Corrugated galvanized sheets, a staple in the metallurgy and energy sectors, are recognized for their durability and versatility. These sheets are made by coating steel or iron with a layer of zinc, which provides excellent corrosion resistance. The corrugated design enhances their strength while allowing for lightweight applications, making them ideal for various construction and industrial uses.

One of the primary benefits of corrugated galvanized sheets is their ability to withstand harsh weather conditions. The zinc coating acts as a barrier against moisture and environmental elements, significantly prolonging the lifespan of the material. This makes them particularly suitable for outdoor applications, such as roofing, siding, and fencing. Their resistance to rust and corrosion ensures that they maintain their aesthetic appeal and structural integrity over time.

In addition to their practical benefits, corrugated galvanized sheets are also easy to install and handle. The lightweight nature of these sheets allows for quicker and more efficient installation, reducing labor costs and time on site. They can be easily cut, shaped, and assembled, making them a popular choice among contractors and builders.

The aesthetic versatility of corrugated galvanized sheets is another aspect worth noting. They can be painted or left in their natural state, providing options for design flexibility. This adaptability allows architects and designers to incorporate them into various styles, from modern industrial to rustic themes.

These sheets are not only limited to construction; they also find applications in the agricultural sector. Farmers often use corrugated galvanized sheets for building barns, storage facilities, and equipment sheds, thanks to their durability and low maintenance requirements. The ability to resist pests and decay adds to their appeal in agricultural environments.

Moreover, corrugated galvanized sheets are an eco-friendly option. The zinc coating can be recycled, and the materials used in their production are sourced from sustainable practices. This aspect resonates with industries aiming to reduce their environmental impact while maintaining functionality and cost-effectiveness.

In summary, corrugated galvanized sheets are a vital component in the metallurgy and energy sectors, offering numerous advantages ranging from durability to aesthetic appeal. Their lightweight nature, ease of installation, and resistance to environmental factors make them an excellent choice for a variety of applications. Whether for construction, agriculture, or industrial uses, understanding the properties and benefits of corrugated galvanized sheets can help you make informed decisions for your projects.

One of the primary benefits of corrugated galvanized sheets is their ability to withstand harsh weather conditions. The zinc coating acts as a barrier against moisture and environmental elements, significantly prolonging the lifespan of the material. This makes them particularly suitable for outdoor applications, such as roofing, siding, and fencing. Their resistance to rust and corrosion ensures that they maintain their aesthetic appeal and structural integrity over time.

In addition to their practical benefits, corrugated galvanized sheets are also easy to install and handle. The lightweight nature of these sheets allows for quicker and more efficient installation, reducing labor costs and time on site. They can be easily cut, shaped, and assembled, making them a popular choice among contractors and builders.

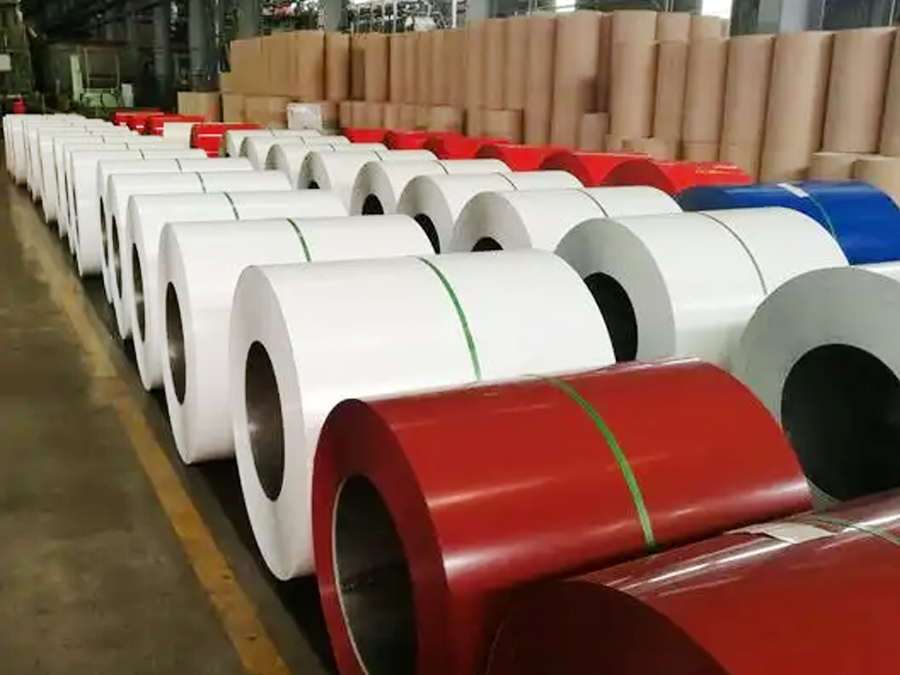

The aesthetic versatility of corrugated galvanized sheets is another aspect worth noting. They can be painted or left in their natural state, providing options for design flexibility. This adaptability allows architects and designers to incorporate them into various styles, from modern industrial to rustic themes.

These sheets are not only limited to construction; they also find applications in the agricultural sector. Farmers often use corrugated galvanized sheets for building barns, storage facilities, and equipment sheds, thanks to their durability and low maintenance requirements. The ability to resist pests and decay adds to their appeal in agricultural environments.

Moreover, corrugated galvanized sheets are an eco-friendly option. The zinc coating can be recycled, and the materials used in their production are sourced from sustainable practices. This aspect resonates with industries aiming to reduce their environmental impact while maintaining functionality and cost-effectiveness.

In summary, corrugated galvanized sheets are a vital component in the metallurgy and energy sectors, offering numerous advantages ranging from durability to aesthetic appeal. Their lightweight nature, ease of installation, and resistance to environmental factors make them an excellent choice for a variety of applications. Whether for construction, agriculture, or industrial uses, understanding the properties and benefits of corrugated galvanized sheets can help you make informed decisions for your projects.

Key words:

RELATED INFORMATION

Understanding Corrugated Galvanized Sheets: Properties, Uses, and Benefits

Corrugated galvanized sheets, a staple in the metallurgy and energy sectors, are recognized for their durability and versatility. These sheets are made by coating steel or iron with a layer of zinc, which provides excellent corrosion resistance. The corrugated design enhances their strength while allowing for lightweight applications, making them ideal for various construction and industrial uses.

2025-09-21

Zinc Coated GI Coils: The Ultimate Solution for Enhanced Corrosion Resistance

Zinc Coated GI Coils: The Ultimate Solution for Enhanced Corrosion Resistance

Table of Contents

Introduction to Zinc Coated GI Coils

What are Zinc Coated GI Coils?

Benefits of Using Zinc Coated GI Coils

Applications of Zinc Coated GI Coils

Types of Zinc Coated GI Coils

Manufacturing Process of Zinc Coated GI Coils

Choosing the Right Supplier for Zinc Coated GI Coils

2025-09-18

Understanding Prepainted Roofing Sheets: Features, Benefits, and Applications

Prepainted roofing sheets, often referred to as color-coated sheets, are metal sheets coated with a layer of paint before they are formed into roofing products. This pre-coating process not only enhances the visual appeal of the roofing material but also provides an extra layer of protection against environmental factors. Typically, these sheets are made from various metals, including galvanized s

2025-09-15