Alu-zinc Coil: A Game Changer in the Roofing Industry

2025-07-26

Alu-zinc Coil: A Game Changer in the Roofing Industry

Table of Contents

1. Introduction to Alu-zinc Coils

2. What is Alu-zinc Coil?

3. Advantages of Alu-zinc Coils in Roofing

4. Applications of Alu-zinc Coils

5. Installation Process of Alu-zinc Coils

6. Maintenance Tips for Alu-zinc Roofing

7. Sustainability and Environmental Impact

8. Frequently Asked Questions

Alu-zinc Coil: A Game Changer in the Roofing Industry

Table of Contents

- 1. Introduction to Alu-zinc Coils

- 2. What is Alu-zinc Coil?

- 3. Advantages of Alu-zinc Coils in Roofing

- 4. Applications of Alu-zinc Coils

- 5. Installation Process of Alu-zinc Coils

- 6. Maintenance Tips for Alu-zinc Roofing

- 7. Sustainability and Environmental Impact

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Alu-zinc Coils

In the ever-evolving landscape of the roofing industry, **Alu-zinc coils** have emerged as a revolutionary material. Combining the benefits of aluminum and zinc, these coils deliver exceptional performance, aesthetics, and longevity. As architects, builders, and homeowners seek better solutions for roofing, Alu-zinc coils stand out as a superior choice, characterized by their resistance to corrosion, lightweight nature, and versatility.

2. What is Alu-zinc Coil?

Alu-zinc coils are made from a substrate of steel that is coated with an alloy of aluminum and zinc. Typically, this alloy contains **55% aluminum, 43.5% zinc**, and **1.5% silicon**. The resulting material boasts superior resistance to oxidation, making it an ideal candidate for various roofing applications. The coating not only protects the core steel from corrosion but also enhances its mechanical properties, enabling it to withstand harsh weather conditions.

The Composition of Alu-zinc Coils

The unique composition of Alu-zinc coils is what sets them apart from traditional galvanized steel. The aluminum content provides a barrier against moisture, while the zinc acts as a sacrificial layer, protecting the steel underneath. This combination results in a material that exhibits exceptional durability and longevity, often lasting two to three times longer than standard galvanized coatings.

3. Advantages of Alu-zinc Coils in Roofing

Choosing Alu-zinc coils for roofing solutions comes with a plethora of advantages:

3.1 Durability and Longevity

Alu-zinc coils are known for their remarkable lifespan. With an average service life of **over 30 years**, they can endure a variety of environmental challenges, including extreme temperatures, humidity, and UV exposure.

3.2 Corrosion Resistance

The innovative coating of **Alu-zinc** offers exceptional resistance to corrosion, making it suitable for coastal areas and regions with high humidity. This resistance ensures that the roofing remains intact and aesthetically pleasing for many years.

3.3 Lightweight and Easy to Handle

Compared to traditional roofing materials, Alu-zinc coils are significantly lighter. This characteristic not only makes them easier to transport but also reduces the structural load on buildings, leading to potential cost savings on foundations and supports.

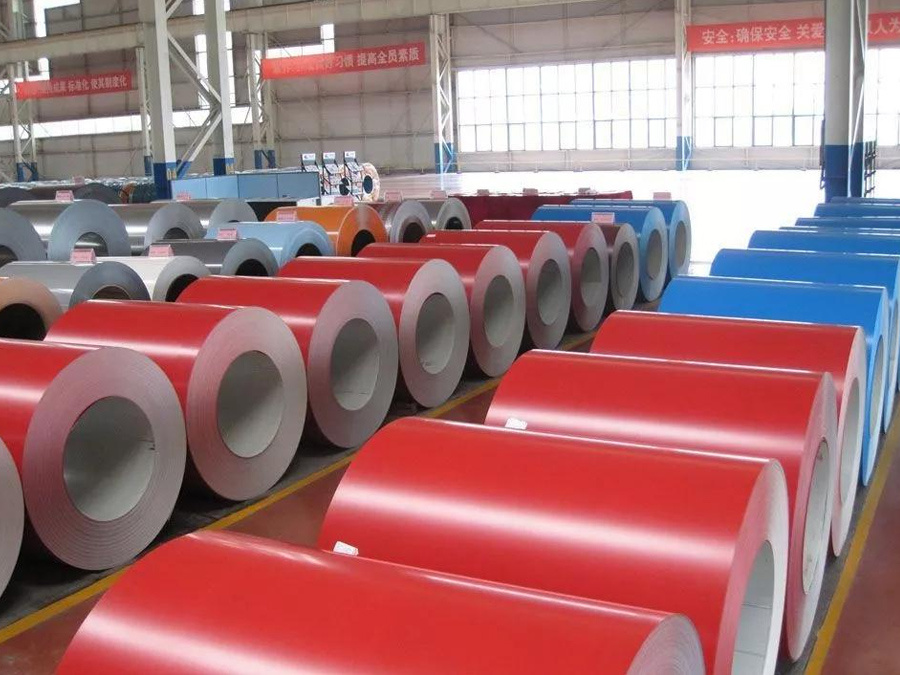

3.4 Aesthetic Appeal

Alu-zinc coils are available in a variety of finishes and colors, allowing designers and homeowners to create visually striking roofing solutions. The shiny, metallic appearance provides a modern look that enhances the overall aesthetic of any building.

4. Applications of Alu-zinc Coils

Alu-zinc coils are versatile and suitable for a range of applications, including:

4.1 Residential Roofing

Homeowners increasingly opt for Alu-zinc roofing due to its durability and visual appeal. Whether for new constructions or renovations, these coils provide a long-lasting solution that enhances property value.

4.2 Commercial Roofing

For commercial buildings, Alu-zinc coils offer robust performance under heavy loads and adverse weather conditions. Their lightweight nature also helps reduce construction costs.

4.3 Industrial Applications

In industrial settings, Alu-zinc coils are utilized for roofing and siding due to their ability to withstand corrosive environments, making them ideal for factories, warehouses, and processing plants.

5. Installation Process of Alu-zinc Coils

The installation of Alu-zinc coils involves several key steps to ensure optimal performance:

5.1 Preparation

Before installation, it is essential to prepare the surface. This includes checking for any existing damage, cleaning the area, and ensuring proper drainage to prevent water accumulation.

5.2 Cutting and Shaping

Alu-zinc coils can be easily cut and shaped to fit the specific dimensions of the roofing structure. This flexibility allows for seamless integration with different architectural styles.

5.3 Securing the Coils

Use appropriate fasteners that are compatible with Alu-zinc material to secure the coils in place. It is crucial to avoid using galvanized fasteners, as they can lead to galvanic corrosion.

5.4 Quality Check

After installation, conduct a thorough quality check to ensure that all seams are properly sealed, and there are no gaps or weak points where water could infiltrate.

6. Maintenance Tips for Alu-zinc Roofing

To maximize the lifespan of Alu-zinc roofing, regular maintenance is essential:

6.1 Routine Inspections

Conduct inspections at least twice a year to assess the condition of the roofing. Look for signs of damage, corrosion, or build-up of debris which can retain moisture.

6.2 Cleaning

Keep the roof clean by removing leaves, dirt, and algae. Use a soft brush or cloth and avoid harsh chemicals that can damage the coating.

6.3 Addressing Minor Repairs

Promptly address any minor repairs to prevent them from escalating into more significant issues. Using the same Alu-zinc material for repairs ensures compatibility and maintains uniformity.

7. Sustainability and Environmental Impact

Alu-zinc coils are not only a practical choice but also an environmentally friendly option for roofing. Their long lifespan reduces the frequency of replacements, minimizing waste. Additionally, the materials are recyclable, contributing to a circular economy.

7.1 Energy Efficiency

The reflective properties of Alu-zinc coatings can help in reducing energy costs by keeping buildings cooler. This energy efficiency is an important consideration for environmentally conscious consumers.

8. Frequently Asked Questions

8.1 What is the lifespan of Alu-zinc roofing?

Alu-zinc roofing typically lasts **30 years or more**, depending on environmental conditions and maintenance practices.

8.2 Is Alu-zinc roofing suitable for coastal areas?

Yes, Alu-zinc coils are highly resistant to corrosion, making them an excellent choice for coastal regions.

8.3 Can Alu-zinc coils be painted?

Yes, Alu-zinc coils can be painted with the appropriate primers and paints. This allows for customization while retaining the benefits of the underlying material.

8.4 How do I maintain my Alu-zinc roof?

Regular inspections, cleaning, and prompt repairs are essential for maintaining Alu-zinc roofing.

8.5 Are Alu-zinc coils environmentally friendly?

Yes, Alu-zinc coils are recyclable and have a long lifespan, making them a sustainable roofing option.

9. Conclusion

In conclusion, Alu-zinc coils represent a significant advancement in roofing technology. Their unique blend of durability, aesthetic appeal, and environmental benefits make them a standout choice for modern roofing solutions. As the industry continues to evolve, embracing materials like Alu-zinc will not only enhance the longevity and performance of roofing systems but also contribute to sustainable building practices. By choosing Alu-zinc coils, homeowners and builders alike invest in a future where quality and sustainability go hand in hand.

Key words:

RELATED INFORMATION

Alu-zinc Coil: A Game Changer in the Roofing Industry

Alu-zinc Coil: A Game Changer in the Roofing Industry

Table of Contents

1. Introduction to Alu-zinc Coils

2. What is Alu-zinc Coil?

3. Advantages of Alu-zinc Coils in Roofing

4. Applications of Alu-zinc Coils

5. Installation Process of Alu-zinc Coils

6. Maintenance Tips for Alu-zinc Roofing

7. Sustainability and Environmental Impact

8. Frequently Asked Questions

2025-07-26

Understanding Corrugated Galvanized Sheets: Applications and Benefits

Corrugated galvanized sheets are a popular choice in the metallurgy and energy sectors, renowned for their strength, durability, and versatility. These sheets are made from steel that has been coated with a layer of zinc, providing excellent resistance to corrosion. The corrugated design, with its wavy pattern, not only adds structural integrity but also enhances their aesthetic appeal.

One of the

2025-07-23

Why Choosing Zinc Coated GI Coils is Essential for Your Construction Projects

Why Choosing Zinc Coated GI Coils is Essential for Your Construction Projects

Table of Contents

1. Introduction to Zinc Coated GI Coils

2. Benefits of Zinc Coated GI Coils in Construction

2.1 Corrosion Resistance

2.2 Durability and Longevity

2.3 Cost-Effectiveness

3. Applications of Zinc Coated GI Coils

3.1 Roofing and Cladding

3.2 Structural Components

4. Environmental Impact of Zinc Coated GI Co

2025-07-20