Why Choosing Zinc Coated GI Coils is Essential for Your Construction Projects

2025-07-20

Why Choosing Zinc Coated GI Coils is Essential for Your Construction Projects

Table of Contents

1. Introduction to Zinc Coated GI Coils

2. Benefits of Zinc Coated GI Coils in Construction

2.1 Corrosion Resistance

2.2 Durability and Longevity

2.3 Cost-Effectiveness

3. Applications of Zinc Coated GI Coils

3.1 Roofing and Cladding

3.2 Structural Components

4. Environmental Impact of Zinc Coated GI Co

Why Choosing Zinc Coated GI Coils is Essential for Your Construction Projects

Table of Contents

1. Introduction to Zinc Coated GI Coils

2. Benefits of Zinc Coated GI Coils in Construction

2.1 Corrosion Resistance

2.2 Durability and Longevity

2.3 Cost-Effectiveness

3. Applications of Zinc Coated GI Coils

3.1 Roofing and Cladding

3.2 Structural Components

4. Environmental Impact of Zinc Coated GI Coils

5. Maintenance Tips for Zinc Coated GI Coils

6. Comparison with Other Coating Options

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Introduction to Zinc Coated GI Coils

Zinc coated galvanized iron (GI) coils are a popular choice in the construction industry due to their unique properties and benefits. These coils are made from iron that has been hot-dipped in zinc, creating a protective layer that significantly enhances their resistance to corrosion and environmental wear. The industry has recognized the importance of choosing the right material for construction projects, and zinc coated GI coils have emerged as a leading option. In this article, we will explore the numerous advantages of zinc coated GI coils and why they should be an integral part of your construction projects.

2. Benefits of Zinc Coated GI Coils in Construction

2.1 Corrosion Resistance

One of the standout features of zinc coated GI coils is their **excellent corrosion resistance**. This characteristic is paramount for construction materials, especially in areas prone to moisture and extreme weather conditions. The zinc layer acts as a sacrificial barrier, meaning that it will corrode before the underlying iron does. This property significantly extends the lifespan of the material, making it a wise investment for builders and contractors.

2.2 Durability and Longevity

When constructed with zinc coated GI coils, buildings exhibit remarkable durability. The strong and resilient nature of these coils ensures they withstand various stresses, including high winds, heavy rainfall, and temperature fluctuations. This durability translates into a **longer service life**, reducing the frequency of repairs and replacements, which is crucial for minimizing long-term costs associated with maintenance.

2.3 Cost-Effectiveness

In the construction industry, budget management is essential. Zinc coated GI coils offer a cost-effective solution due to their longevity and low maintenance requirements. While the initial investment may be slightly higher than other materials, the overall lifecycle cost is significantly lower. By opting for zinc coated GI coils, you are choosing a material that balances upfront costs with long-term savings, making it a smart choice for any construction project.

3. Applications of Zinc Coated GI Coils

Zinc coated GI coils are incredibly versatile and can be used in various construction applications. Here are some of the most common uses:

3.1 Roofing and Cladding

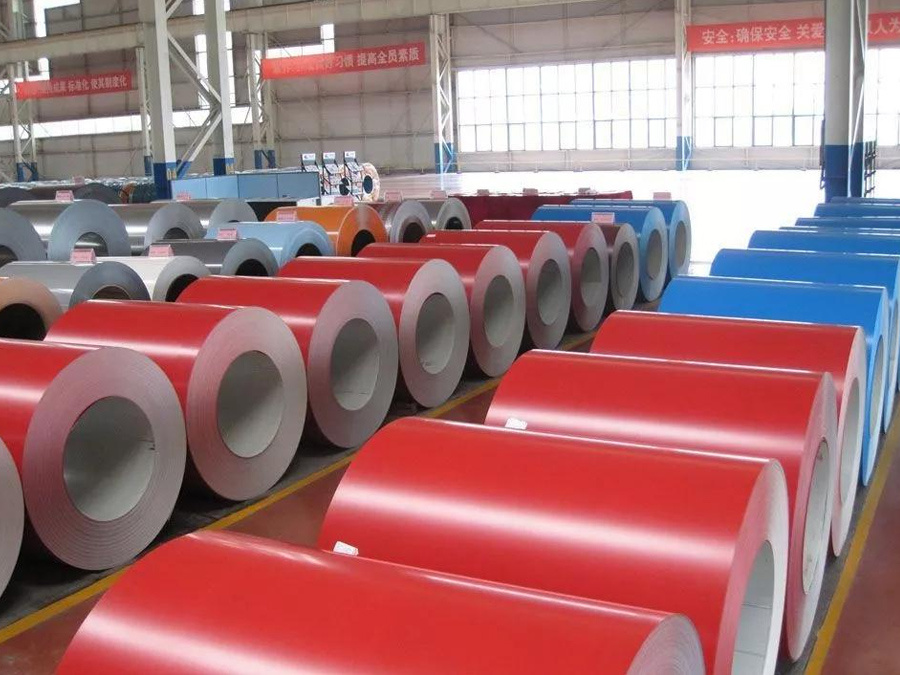

Zinc coated GI coils are widely used in roofing and cladding applications due to their excellent weather resistance and aesthetic appeal. Architects and builders appreciate the sleek look of these coils, which can be painted or left in their metallic finish to suit the design of the structure. Additionally, their lightweight nature makes installation easier, contributing to faster project timelines.

3.2 Structural Components

In addition to roofing and cladding, zinc coated GI coils are also ideal for creating structural components such as beams, columns, and trusses. Their strength and resistance to corrosion make them suitable for both residential and commercial buildings. This adaptability allows for creative architectural designs without compromising structural integrity.

4. Environmental Impact of Zinc Coated GI Coils

Choosing zinc coated GI coils is not just a smart business decision but also an environmentally friendly one. The production process of these coils is designed to minimize waste and energy consumption. Furthermore, zinc is a naturally occurring element that is fully recyclable. At the end of their lifecycle, zinc coated GI coils can be repurposed, reducing landfill waste and promoting sustainability in the construction industry.

5. Maintenance Tips for Zinc Coated GI Coils

To ensure the longevity of zinc coated GI coils, proper maintenance is essential. Here are some practical tips:

- **Regular Inspection**: Check for any signs of wear or damage regularly. Early detection can prevent more significant issues later.

- **Cleaning**: Keep the surface clean from dirt, debris, and pollutants. A simple wash with water and a mild detergent is often sufficient.

- **Touch-Up Paint**: If the protective zinc layer gets scratched, consider applying touch-up paint to prevent corrosion from setting in.

6. Comparison with Other Coating Options

When discussing coatings for construction materials, it's important to compare zinc coated GI coils with alternatives. Other options include galvanized steel, painted steel, and aluminum. While each material has its own set of benefits, zinc coated GI coils provide a unique blend of corrosion resistance, durability, and cost-effectiveness that often surpasses the competition. For instance, painted steel may offer aesthetic choices, but without the zinc layer, it lacks the same level of corrosion resistance.

7. Frequently Asked Questions (FAQs)

What are zinc coated GI coils made of?

Zinc coated GI coils are primarily made of galvanized iron, which is iron that has been coated with zinc to enhance its corrosion resistance.

How long do zinc coated GI coils last?

With proper maintenance, zinc coated GI coils can last for decades, often exceeding 50 years, depending on environmental conditions and usage.

Can zinc coated GI coils be recycled?

Yes, zinc coated GI coils are fully recyclable, making them an environmentally friendly choice for construction projects.

Are zinc coated GI coils suitable for coastal areas?

Absolutely! Their superior corrosion resistance makes them an excellent choice for coastal applications where exposure to saltwater is a concern.

How do I choose the right thickness for my project?

Choosing the right thickness depends on the specific application and load requirements. Consulting with a structural engineer can help determine the best option for your project.

8. Conclusion

In summary, zinc coated GI coils represent an outstanding choice for construction projects, combining **durability, cost-effectiveness, and environmental friendliness**. Their versatility in applications such as roofing, cladding, and structural components makes them an invaluable asset in modern construction practices. As the industry continues to evolve, choosing materials that offer both performance and sustainability will be crucial for future developments. By selecting zinc coated GI coils, you ensure a robust foundation for your projects that will stand the test of time, ultimately leading to greater satisfaction and success in your construction endeavors.

Key words:

RELATED INFORMATION

Why Choosing Zinc Coated GI Coils is Essential for Your Construction Projects

Why Choosing Zinc Coated GI Coils is Essential for Your Construction Projects

Table of Contents

1. Introduction to Zinc Coated GI Coils

2. Benefits of Zinc Coated GI Coils in Construction

2.1 Corrosion Resistance

2.2 Durability and Longevity

2.3 Cost-Effectiveness

3. Applications of Zinc Coated GI Coils

3.1 Roofing and Cladding

3.2 Structural Components

4. Environmental Impact of Zinc Coated GI Co

2025-07-20

Understanding Prepainted Roofing Sheets: Benefits, Applications, and Features

Prepainted roofing sheets have become increasingly popular in the construction and roofing sectors due to their versatility and durability. These sheets are made from steel or aluminum substrates that are coated with a layer of paint before being processed into various shapes and sizes. This prepainting process offers numerous advantages that make prepainted roofing sheets an ideal solution for a

2025-07-17

Zn-Al-Mg Coated Steel Coil: The Ultimate Solution for High-Performance Building Structures

Zn-Al-Mg Coated Steel Coil: The Ultimate Solution for High-Performance Building Structures

Table of Contents

1. Introduction to Zn-Al-Mg Coated Steel Coil

2. What is Zn-Al-Mg Coating?

3. Advantages of Using Zn-Al-Mg Coated Steel

3.1 Exceptional Corrosion Resistance

3.2 Superior Heat Resistance

3.3 Enhanced Mechanical Properties

2025-07-14