Zn-Al-Mg Coated Steel Coil: The Ultimate Solution for High-Performance Building Structures

2025-07-14

Zn-Al-Mg Coated Steel Coil: The Ultimate Solution for High-Performance Building Structures

Table of Contents

1. Introduction to Zn-Al-Mg Coated Steel Coil

2. What is Zn-Al-Mg Coating?

3. Advantages of Using Zn-Al-Mg Coated Steel

3.1 Exceptional Corrosion Resistance

3.2 Superior Heat Resistance

3.3 Enhanced Mechanical Properties

Zn-Al-Mg Coated Steel Coil: The Ultimate Solution for High-Performance Building Structures

Table of Contents

- 1. Introduction to Zn-Al-Mg Coated Steel Coil

- 2. What is Zn-Al-Mg Coating?

- 3. Advantages of Using Zn-Al-Mg Coated Steel

- 3.1 Exceptional Corrosion Resistance

- 3.2 Superior Heat Resistance

- 3.3 Enhanced Mechanical Properties

- 4. Applications of Zn-Al-Mg Coated Steel Coil

- 5. Sustainability of Zn-Al-Mg Coated Steel

- 6. Cost-Effectiveness of Zn-Al-Mg Coated Steel

- 7. Future Trends in Zn-Al-Mg Coated Steel Use

- 8. Conclusion

1. Introduction to Zn-Al-Mg Coated Steel Coil

In the construction industry, the selection of materials plays a crucial role in determining the durability and performance of structures. Among various options available, **Zn-Al-Mg coated steel coil** has emerged as a front-runner due to its exceptional properties. This innovative material combines zinc, aluminum, and magnesium in a unique coating that offers unparalleled performance and longevity.

This article delves into the characteristics, advantages, applications, and sustainability aspects of Zn-Al-Mg coated steel coil, positioning it as the ultimate choice for high-performance structures.

2. What is Zn-Al-Mg Coating?

Zn-Al-Mg coating is a specialized metallic coating applied to steel substrates to enhance their corrosion resistance and mechanical properties. The coating consists of a blend of:

- **Zinc (Zn)**: Provides sacrificial corrosion protection.

- **Aluminum (Al)**: Enhances the barrier effect, providing additional resistance to corrosion.

- **Magnesium (Mg)**: Improves the overall structural integrity and enhances the coating’s resistance to environmental factors.

This combination not only prolongs the lifespan of steel components but also enables them to withstand harsh environments without significant degradation.

3. Advantages of Using Zn-Al-Mg Coated Steel

The use of Zn-Al-Mg coated steel coil offers several advantages over traditional steel coatings, making it the preferred choice for various applications.

3.1 Exceptional Corrosion Resistance

One of the standout features of Zn-Al-Mg coated steel is its **exceptional corrosion resistance**. The zinc component acts as a sacrificial anode, effectively protecting the underlying steel from oxidation. The presence of aluminum and magnesium further enhances this protective barrier, making Zn-Al-Mg coated steel suitable for even the most corrosive environments, including coastal areas and industrial zones.

3.2 Superior Heat Resistance

Zn-Al-Mg coated steel exhibits remarkable **heat resistance**, making it suitable for applications exposed to high temperatures. The aluminum in the coating helps maintain structural integrity and prevents oxidation at elevated temperatures, providing an added layer of safety in construction and manufacturing applications.

3.3 Enhanced Mechanical Properties

The incorporation of magnesium enhances the **mechanical properties** of Zn-Al-Mg coated steel, including tensile strength and ductility. This increased strength allows for thinner gauge sheets to be used, reducing material costs while maintaining the structural performance of the final product.

4. Applications of Zn-Al-Mg Coated Steel Coil

The versatility of Zn-Al-Mg coated steel makes it suitable for a wide range of applications across different industries.

4.1 Use in Construction

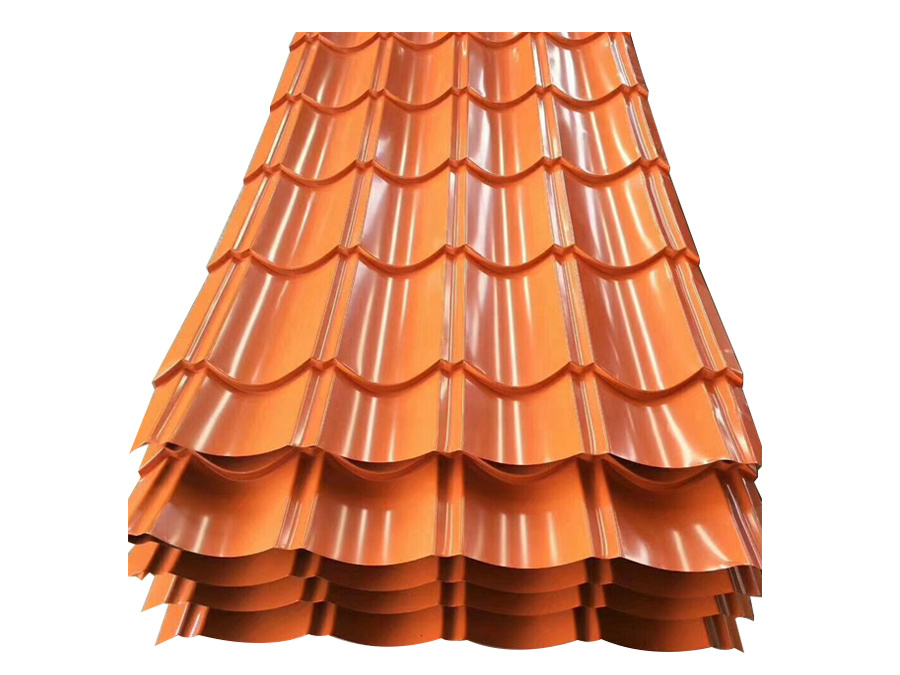

In the construction sector, Zn-Al-Mg coated steel is utilized for roofing, siding, and structural components. Its long-lasting durability and low maintenance requirements make it an attractive solution for residential, commercial, and industrial buildings.

4.2 Application in Automotive Industries

The automotive industry benefits from Zn-Al-Mg coated steel in the manufacturing of body panels, frames, and other components. The material’s corrosion resistance and lightweight nature contribute to improved vehicle performance and longevity.

4.3 Home Appliance Manufacturing

Home appliances often require materials that can withstand frequent use and exposure to moisture. Zn-Al-Mg coated steel is used in manufacturing various appliances such as refrigerators, washing machines, and ovens, thanks to its durability and aesthetic appeal.

5. Sustainability of Zn-Al-Mg Coated Steel

In today’s eco-conscious world, sustainability is a key consideration in material selection. Zn-Al-Mg coated steel is not only durable but also recyclable, making it an environmentally friendly choice. Its long lifespan reduces the need for frequent replacement, leading to lower overall consumption of resources and energy.

Furthermore, the production of Zn-Al-Mg coated steel involves lower energy consumption compared to many other steel coatings, contributing to a reduced carbon footprint.

6. Cost-Effectiveness of Zn-Al-Mg Coated Steel

When evaluating material options, cost-effectiveness is crucial. Although the initial investment in Zn-Al-Mg coated steel may be higher than traditional options, the long-term savings are significant. The durability and low maintenance needs translate into reduced lifecycle costs, making it a worthwhile investment for builders and manufacturers alike.

7. Future Trends in Zn-Al-Mg Coated Steel Use

The future of Zn-Al-Mg coated steel looks promising, with several trends emerging in the construction and manufacturing sectors.

- **Innovation in Coating Technologies**: Advances in coating processes are expected to enhance the performance of Zn-Al-Mg coated steel further.

- **Increased Demand for Sustainable Materials**: As industries shift towards eco-friendly practices, the demand for Zn-Al-Mg coated steel is likely to rise due to its sustainable attributes.

- **Growth in High-Performance Applications**: With ongoing developments in construction and automotive technologies, the application of Zn-Al-Mg coated steel in high-performance environments will expand.

8. Conclusion

In conclusion, Zn-Al-Mg coated steel coil is undoubtedly the **ultimate solution for high-performance structures**. Its exceptional corrosion resistance, superior heat resistance, and enhanced mechanical properties make it a standout choice for various applications in construction, automotive, and home appliance manufacturing.

As sustainability becomes increasingly important, the eco-friendly nature of Zn-Al-Mg coated steel further solidifies its position as a preferred material in modern engineering. The long-term cost-effectiveness of this innovative product ensures that it will remain at the forefront of building materials for years to come.

Embracing Zn-Al-Mg coated steel is not just a choice for today but an investment in a more durable and sustainable future.

FAQs

1. What is Zn-Al-Mg coated steel coil?

Zn-Al-Mg coated steel coil is a type of steel with a protective coating made of zinc, aluminum, and magnesium, designed to enhance its corrosion resistance and mechanical properties.

2. How does Zn-Al-Mg coating improve corrosion resistance?

The zinc in the coating acts as a sacrificial anode, protecting the underlying steel, while aluminum and magnesium provide additional barriers against corrosion.

3. Can Zn-Al-Mg coated steel be recycled?

Yes, Zn-Al-Mg coated steel is fully recyclable, making it an environmentally friendly choice for construction and manufacturing.

4. What industries benefit from Zn-Al-Mg coated steel?

Key industries include construction, automotive, and home appliance manufacturing, where durability and corrosion resistance are essential.

5. Is Zn-Al-Mg coated steel cost-effective?

While the initial cost may be higher than traditional steel, its longevity and low maintenance needs make it a cost-effective choice over its lifecycle.

Key words:

RELATED INFORMATION

Zn-Al-Mg Coated Steel Coil: The Ultimate Solution for High-Performance Building Structures

Zn-Al-Mg Coated Steel Coil: The Ultimate Solution for High-Performance Building Structures

Table of Contents

1. Introduction to Zn-Al-Mg Coated Steel Coil

2. What is Zn-Al-Mg Coating?

3. Advantages of Using Zn-Al-Mg Coated Steel

3.1 Exceptional Corrosion Resistance

3.2 Superior Heat Resistance

3.3 Enhanced Mechanical Properties

2025-07-14

Unlocking the Potential of Customized Prepainted Steel Plates in Construction

In the construction and decorative materials sector, the use of customized prepainted steel plates has become increasingly popular due to their unique advantages. These plates are coated with a layer of paint before they are shaped and installed, allowing for a plethora of design options and functionalities that cater to specific project needs.

One of the foremost benefits of customizing prepainte

2025-07-11

Exploring the Benefits of Aluzinc Steel Plates in Modern Construction

Exploring the Benefits of Aluzinc Steel Plates in Modern Construction

Table of Contents

1. Introduction to Aluzinc Steel Plates

2. What is Aluzinc Steel?

3. Key Benefits of Aluzinc Steel Plates

3.1 Superior Corrosion Resistance

3.2 Exceptional Durability and Longevity

3.3 Cost-Effectiveness

3.4 Aesthetic Appeal

4. Applications of Aluzinc Steel Plates in Construction

5. Comparing Aluzin

2025-07-10