Understanding PPGI Plates: Properties, Applications, and Benefits

2025-08-10

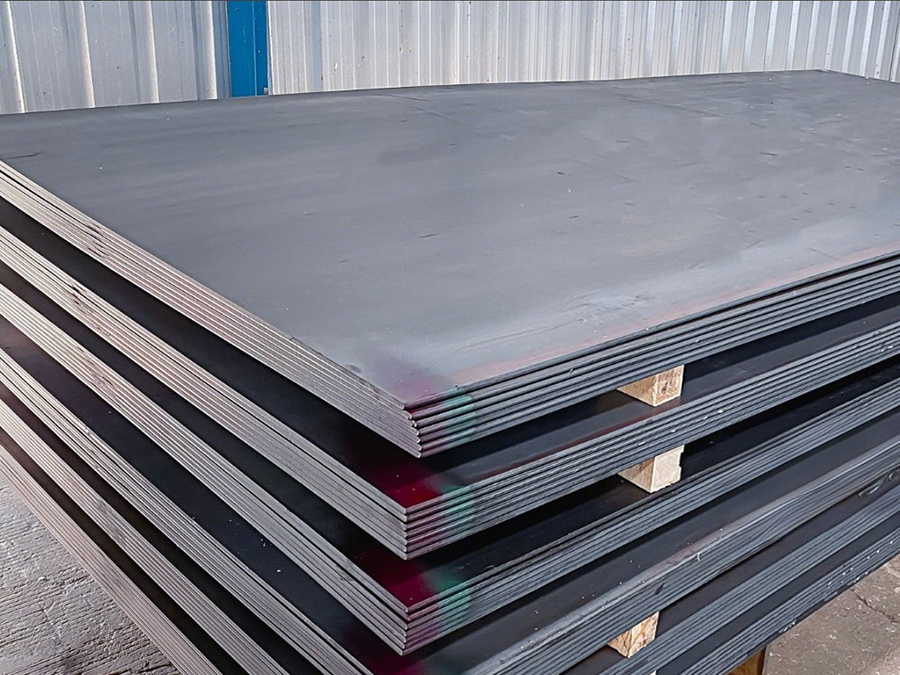

PPGI, or Pre-Painted Galvanized Iron, is a type of steel that has been coated with a layer of zinc for corrosion resistance and then pre-painted to enhance its aesthetic appeal and durability. In the metallurgy and energy sector, PPGI plates play a significant role due to their versatile properties and wide range of applications.

One of the primary features of PPGI plates is their excellent corros

PPGI, or Pre-Painted Galvanized Iron, is a type of steel that has been coated with a layer of zinc for corrosion resistance and then pre-painted to enhance its aesthetic appeal and durability. In the metallurgy and energy sector, PPGI plates play a significant role due to their versatile properties and wide range of applications.

One of the primary features of PPGI plates is their excellent corrosion resistance. The zinc coating acts as a barrier to protect the underlying steel from rust and degradation, which is crucial in industries that require long-lasting materials. This resistance is enhanced by the pre-painted layer, which not only adds color but also provides an additional protective barrier against environmental factors such as moisture and pollutants.

PPGI plates are manufactured through a process that involves galvanizing steel sheets and then applying a layer of paint. This process typically includes cleaning the steel substrate, applying a zinc coating through hot-dip galvanizing, and finally applying one or more layers of paint. The paints used can vary widely, offering different colors and finishes to suit various aesthetic needs. The result is a material that is not only functional but also visually appealing.

In terms of applications, PPGI plates are commonly used in construction, automotive, and manufacturing industries. They are often employed in building facades, roofing sheets, and interior cladding due to their lightweight nature and ease of installation. Additionally, PPGI plates are favored in the production of appliances, where both durability and design are important.

The benefits of using PPGI plates extend beyond their physical properties. Their lightweight nature contributes to reduced transportation costs and ease of handling, while the pre-painted surfaces minimize the need for additional finishes, saving time and labor costs in construction and manufacturing processes. Furthermore, PPGI plates are recyclable, making them a more sustainable option compared to other materials.

In summary, PPGI plates are an integral part of the metallurgy and energy sectors, known for their corrosion resistance, aesthetic versatility, and wide-ranging applications. Understanding the features and benefits of PPGI plates can help industries make informed decisions when selecting materials for their projects. Whether for construction, manufacturing, or automotive applications, PPGI plates offer a combination of durability, design, and efficiency that makes them a preferred choice in today’s market.

One of the primary features of PPGI plates is their excellent corrosion resistance. The zinc coating acts as a barrier to protect the underlying steel from rust and degradation, which is crucial in industries that require long-lasting materials. This resistance is enhanced by the pre-painted layer, which not only adds color but also provides an additional protective barrier against environmental factors such as moisture and pollutants.

PPGI plates are manufactured through a process that involves galvanizing steel sheets and then applying a layer of paint. This process typically includes cleaning the steel substrate, applying a zinc coating through hot-dip galvanizing, and finally applying one or more layers of paint. The paints used can vary widely, offering different colors and finishes to suit various aesthetic needs. The result is a material that is not only functional but also visually appealing.

In terms of applications, PPGI plates are commonly used in construction, automotive, and manufacturing industries. They are often employed in building facades, roofing sheets, and interior cladding due to their lightweight nature and ease of installation. Additionally, PPGI plates are favored in the production of appliances, where both durability and design are important.

The benefits of using PPGI plates extend beyond their physical properties. Their lightweight nature contributes to reduced transportation costs and ease of handling, while the pre-painted surfaces minimize the need for additional finishes, saving time and labor costs in construction and manufacturing processes. Furthermore, PPGI plates are recyclable, making them a more sustainable option compared to other materials.

In summary, PPGI plates are an integral part of the metallurgy and energy sectors, known for their corrosion resistance, aesthetic versatility, and wide-ranging applications. Understanding the features and benefits of PPGI plates can help industries make informed decisions when selecting materials for their projects. Whether for construction, manufacturing, or automotive applications, PPGI plates offer a combination of durability, design, and efficiency that makes them a preferred choice in today’s market.

Key words:

RELATED INFORMATION

Understanding PPGI Plates: Properties, Applications, and Benefits

PPGI, or Pre-Painted Galvanized Iron, is a type of steel that has been coated with a layer of zinc for corrosion resistance and then pre-painted to enhance its aesthetic appeal and durability. In the metallurgy and energy sector, PPGI plates play a significant role due to their versatile properties and wide range of applications.

One of the primary features of PPGI plates is their excellent corros

2025-08-10

Evaluating the Performance of HRB400 Rebar in Various Conditions: A Comprehensive Analysis

Evaluating the Performance of HRB400 Rebar in Various Conditions

Table of Contents

1. Introduction to HRB400 Rebar

2. Mechanical Properties of HRB400 Rebar

3. Durability and Corrosion Resistance

4. Performance of HRB400 Rebar in Various Environmental Conditions

5. Applications of HRB400 Rebar in the Construction Industry

6. Testing Methods for Evaluating HRB400 Rebar

7. Case Studies

2025-08-07

Understanding Galvalume Steel Coil/Plate: A Comprehensive Overview

Galvalume steel coil/plate is an innovative product that combines the advantages of both zinc and aluminum in the coating process, resulting in a highly durable and corrosion-resistant metal. This material is primarily composed of a base steel substrate that is coated with a mixture of aluminum and zinc, typically in a ratio of 55% aluminum to 43.4% zinc, with the remaining percentage being silico

2025-08-04