Choosing the Right Prepainted Steel Coil Manufacturer for Your Construction Needs

2025-06-14

Choosing the Right Prepainted Steel Coil Manufacturer for Your Construction Needs

When embarking on a construction project, selecting the right materials is crucial for ensuring durability, aesthetic appeal, and overall success. Among these materials, **prepainted steel coils** stand out due to their versatility and strength. However, not all manufacturers are created equal. In this comprehensive

Choosing the Right Prepainted Steel Coil Manufacturer for Your Construction Needs

When embarking on a construction project, selecting the right materials is crucial for ensuring durability, aesthetic appeal, and overall success. Among these materials, **prepainted steel coils** stand out due to their versatility and strength. However, not all manufacturers are created equal. In this comprehensive guide, we delve into how to choose the right prepainted steel coil manufacturer to meet your unique construction needs.

Understanding Prepainted Steel Coils

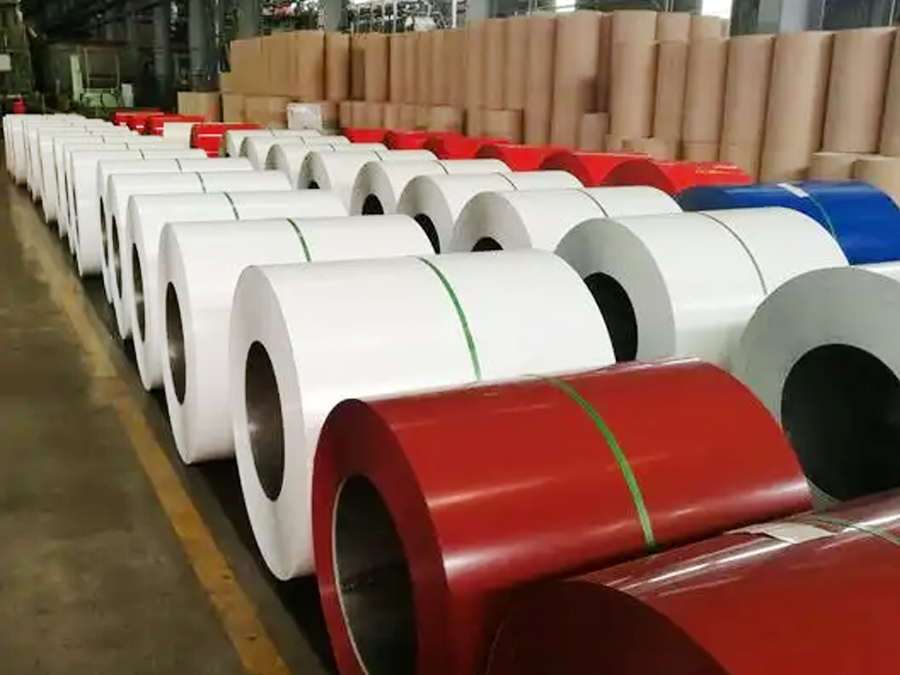

Before diving into the selection process, let’s clarify what prepainted steel coils are. These products are steel sheets coated with a layer of paint before being shipped for use. This pre-treatment not only enhances the appearance but also offers additional protection against corrosion and wear.

Benefits of Using Prepainted Steel Coils

The choice of prepainted steel coils brings numerous advantages to the table:

1. **Aesthetic Flexibility**: Available in various colors and finishes, they allow for greater design freedom.

2. **Enhanced Durability**: The paint acts as a protective barrier, prolonging the lifespan of the steel.

3. **Cost-Effectiveness**: They often require less maintenance over time, translating to lower long-term costs.

4. **Sustainable Choice**: Many manufacturers now offer eco-friendly options that minimize environmental impact.

Key Factors to Consider When Choosing a Manufacturer

Selecting the right manufacturer involves evaluating several factors that can significantly impact the quality and reliability of your materials.

1. Reputation in the Industry

A manufacturer's reputation is paramount. A well-established company often has a proven track record of quality and reliability. Look for online reviews, testimonials, and case studies that highlight customer satisfaction.

2. Quality Assurance Standards

Ensure the manufacturer adheres to strict quality assurance standards. Certifications such as ISO 9001 can indicate a commitment to maintaining high production standards, which directly affects the quality of the prepainted steel coils.

3. Range of Products

Evaluate the breadth of the manufacturer’s product line. A diverse range of prepainted steel coils allows you to select the exact specifications needed for your project, including thickness, color, and coating type.

Product Customization Options

Customization capabilities can be a game-changer. Manufacturers that allow for tailored solutions can better meet your unique requirements, ensuring that the materials perfectly fit your project.

4. Production Capacity and Lead Times

Understanding a manufacturer’s production capacity and lead times is essential. For large-scale projects, select a company that can meet high volume demands without compromising on quality or timelines.

5. Technological Advancements

Investing in manufacturers that utilize the latest technology ensures enhanced production processes and product quality. Advanced machinery can lead to better coating application and finish consistency.

6. Customer Service and Support

Evaluate the level of customer service provided by the manufacturer. A responsive support team can assist you with inquiries and issues, facilitating smooth communication throughout the project.

7. Pricing and Payment Terms

While cost should not be the sole deciding factor, it’s important to compare pricing structures among different manufacturers. Look for transparent pricing and flexible payment options that suit your budget and financial planning.

8. Delivery and Logistics

Consider the logistics of delivery. Reliable manufacturers will have efficient shipping arrangements that ensure timely delivery of your materials, minimizing delays in your construction schedule.

Researching Potential Manufacturers

Once you are aware of what to look for, the next step is conducting thorough research on potential manufacturers.

1. Online Research and Directories

Utilize online platforms and directories to create a list of potential manufacturers. Websites such as ThomasNet and Alibaba can provide valuable insights into various companies and their offerings.

2. Industry Associations

Membership in industry associations often indicates commitment to quality and ethical practices. Look for manufacturers affiliated with organizations such as the National Coil Coating Association (NCCA).

3. Trade Shows and Expos

Attending industry trade shows allows you to meet manufacturers in person. These events provide opportunities for networking and firsthand evaluation of products.

Questions to Ask Potential Manufacturers

When you narrow down your list, prepare specific questions to ask potential manufacturers to further assess their capabilities.

1. What are your production processes for prepainted steel coils?

Understanding the production process can give you insights into quality control measures.

2. Can you provide samples of your prepainted steel coils?

Requesting samples allows you to evaluate the quality and finish of the products before making a commitment.

3. What is your warranty policy?

A solid warranty policy demonstrates confidence in the product and provides you with peace of mind.

4. How do you handle customer complaints or issues?

Understanding the manufacturer’s approach to customer service will help gauge their commitment to client satisfaction.

5. What are your lead times for large orders?

Establishing lead times is crucial for project planning and timelines.

Evaluating Manufacturer Proposals

Once you have received proposals from potential manufacturers, it’s time to evaluate them critically.

1. Compare Pricing and Value

While price is important, consider the value each manufacturer offers. A lower price may not guarantee superior quality, so weigh the benefits carefully.

2. Assess Delivery Schedules

Ensure the proposed delivery schedules align with your project timelines to avoid unnecessary delays.

3. Review Terms and Conditions

Pay close attention to the terms of service, including payment terms, return policies, and warranties.

Finalizing Your Decision

After thorough research and evaluation, it’s time to make your choice.

1. Trust Your Instincts

While data and research are crucial, gut feelings about a manufacturer should not be overlooked. Trust your instincts based on the interactions and presentations you experienced.

2. Build a Strong Partnership

Once you’ve made your selection, foster a good relationship with the manufacturer. Open communication can lead to a more successful partnership.

FAQs About Prepainted Steel Coil Manufacturers

1. What are prepainted steel coils made of?

Prepainted steel coils are made from high-quality steel sheets that undergo a coating process to enhance durability and aesthetic appeal.

2. How long do prepainted steel coils last?

With proper maintenance, prepainted steel coils can last 20 years or more, depending on the coating and environmental factors.

3. Are custom colors available for prepainted steel coils?

Yes, many manufacturers offer a variety of colors and finishes, and custom colors can often be created upon request.

4. What is the typical lead time for prepainted steel coil orders?

Lead times can vary widely, but most manufacturers can provide an estimate based on order volume and current production capacity.

5. How should prepainted steel coils be stored before installation?

Prepainted steel coils should be stored in a dry, ventilated area, away from direct sunlight and moisture to prevent corrosion.

Conclusion

Choosing the right prepainted steel coil manufacturer is a critical step in ensuring the success of your construction projects. By taking the time to assess potential manufacturers based on reputation, quality standards, product range, and customer service, you can secure materials that not only meet but exceed your expectations. Remember, investing in quality now will save you time and costs in the future, paving the way for a successful construction journey.

Key words:

RELATED INFORMATION

Understanding Color Coated Steel Coil Manufacturing for Construction and Decoration

Color coated steel coils are an essential material in the building and decoration sector, favored for their versatility and aesthetic appeal. These coils are typically made from galvanized or galvalume steel, which undergoes a series of processes to enhance their durability and visual characteristics. The primary process involves applying a layer of protective paint, providing not only a vibrant c

2025-06-15

Choosing the Right Prepainted Steel Coil Manufacturer for Your Construction Needs

Choosing the Right Prepainted Steel Coil Manufacturer for Your Construction Needs

When embarking on a construction project, selecting the right materials is crucial for ensuring durability, aesthetic appeal, and overall success. Among these materials, **prepainted steel coils** stand out due to their versatility and strength. However, not all manufacturers are created equal. In this comprehensive

2025-06-14

Understanding the Benefits and Applications of In Stock Aluzinc Steel Coil

Aluzinc steel coil, a popular material in the metallurgy and energy industries, features a distinctive coating that combines aluminum and zinc. This innovative coating provides remarkable corrosion resistance, making aluzinc steel coil an ideal choice for various applications. When you come across the term "in stock aluzinc steel coil," it signifies that these products are readily available for im

2025-06-13